Sliding Contact Bearing

Thick Film Lubrication

In this, two surface of bearing in relative motion are completely separated by a film of fluid. Thus surface friction has no role, it has two types:

Hydrodynamic Bearing

In hydrodynamic bearing, load-supporting fluid is created by shape and relative motion of sliding surfaces. It is not necessary to supply the lubricant under pressure. The only requirement is sufficient and continuous supply. Its main application is in engine centrifugal pump.

Remember:

- Bearing which operate without lubricant is called zero film bearing.

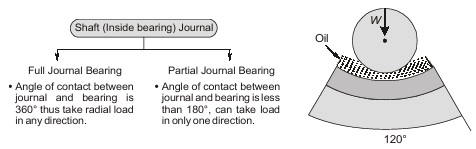

- Journal Bearing: It is a sliding contact bearing working on hydro-dynamic lubrication, support the load in

radial direction. It has two types:

Hydro-Static bearing

In this system, load supporting fluid film separating two surfaces is created by external source like pump supplying sufficient fluid under pressure. Thus, it is also called externally pressurized bearing, it is used in centrifuges ball mills and vertical turbo generator.

Advantages:

- High load carrying capacity

- Starting friction is absent

- There is no rubbing action

Thin Film Lubrication

Lubricant film is relatively thin and there is partial to metal contact. In this lubrication, under excessive load, less oil supply, low speed, misalignment, boundary lubrication will occur. Performance of bearing under boundary lubrication will depend upon.

- Chemical composition of lubricating oil.

- Surface roughness.

Remember:

Under excessive load and low speed, hydro-dynamic bearing also operates under boundary lubrication.

Measurement of Viscosity

Saybolt Universal Second (SUS), Zk = 0.22t – 180/t

Here, Zk = Kinematic viscosity, t = Viscosity in SUS

<< Previous | Next >>

Must Read: What is Machine Design?

Dear Aspirants,

Your preparation for GATE, ESE, PSUs, and AE/JE is now smarter than ever — thanks to the MADE EASY YouTube channel.

This is not just a channel, but a complete strategy for success, where you get toppers strategies, PYQ–GTQ discussions, current affairs updates, and important job-related information, all delivered by the country’s best teachers and industry experts.

If you also want to stay one step ahead in the race to success, subscribe to MADE EASY on YouTube and stay connected with us on social media.

MADE EASY — where preparation happens with confidence.

MADE EASY is a well-organized institute, complete in all aspects, and provides quality guidance for both written and personality tests. MADE EASY has produced top-ranked students in ESE, GATE, and various public sector exams. The publishing team regularly writes exam-related blogs based on conversations with the faculty, helping students prepare effectively for their exams.