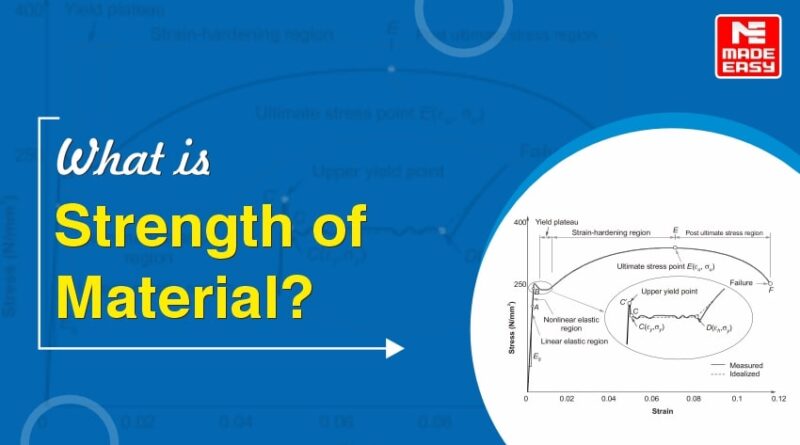

What is Strength of Material?

Strength of Material – CE (Civil Engineering)

Strength of material is a branch of applied mechanics that deals with the behavior of solid bodies subjected to various types of loading and internal forces developed due to these loading. A thorough understanding of mechanical behaviour essential for the safe design of all structures, whether buildings, bridges, machines, motors, submarines or airplanes. Hence, strength of materials is a basic subject in many engineering fields.

The objective of this analysis will be to determine the stresses, strains and deflections produced by the loads in different structures. Theoretical analysis and experimental results have equally important roles in the study of strength of materials. So these quantities are found for all values of load up to the failure load, and then we will have a complete picture of the mechanical behaviour of the body.

The behaviour of a member subjected to forces depends not only on the fundamental law of Newtonian mechanics that governs the equilibrium of the forces but also on the mechanical characteristics of materials of which the member is fabricated. Sometimes, to predict the behaviour of material some necessary information regarding the characteristics of materials comes from laboratory tests.

Given below are the links to some major and important topics related to strength of material that will be beneficial for aspiring civil engineers.

Key Concepts:

- Stress

- Loading Diagram from BMD

- Shear Force and Bending Moment Diagram

- Simple Bending or Pure Bending

- Principal Stresses and Maximum Shear Stress

- Composite Beams

- Beam of Uniform Strength

- Hooke Law for Plane Stress

- Transformation Equations for Plane Strain

- Shear Stress Distribution in Circular Section

- Euler Theory for Buckling Failure

Strain

Strain is defined as the change in dimension with respect to the original dimension. Strains are of following types:

- Axial Strain: Strain in the direction of applied force is known as axial strain or longitudinal strain. It is the ratio of change in the linear dimension to the original linear dimension of the member.

- Lateral Strain: Strain in the perpendicular direction of the applied force is known as lateral strain. It is the ratio of change of lateral dimension to the original lateral dimension of the member.

- Shear Strain: Shear strains are angular deformation caused by shearing force.

An axially loaded bar undergoes a change in length, becoming longer when in tension and shorter when in compression. The elongation or shortening in axially loaded members per unit length is known as strain.

Strain is dimensionless quantity and is always expressed in the form of a number. If the member is in tension then the strain is called tensile strain. If the member is in compression, then the strain is compressive strain.

On the basis of length of member used in calculation of strain, strain can be of following two types:

- Engineering or Nominal Strain

- True or Actual Strain

Principal Stress and Strain

Principal stresses are the normal stresses acting on particular planes where shear stress is zero. In a three-dimensional state of stress, there are three principal stresses, denoted as σ1 , σ2 , and σ3. Understanding principal stresses is crucial for predicting failure modes in materials, as they indicate the maximum and minimum normal stresses experienced by a material.

Principal strains are the strains that occur in the material along the principal axes, which are the directions where the normal strain is maximized or minimized, and shear strain is zero. Similar to principal stresses, there are three principal strains, denoted as ϵ1 ,ϵ2 , and ϵ3. Principal strains help in understanding how a material deforms under load and are essential for assessing material behavior, including yielding and failure.

- Principal Stresses: Maximum and minimum normal stresses at which shear stress is zero.

- Principal Strains: Maximum and minimum strains occurring along specific axes with zero shear strain.

Shear Force and Bending Moment

In strength of materials (SOM), shear force is the force that acts parallel to the cross-section of a structural member, attempting to shear it apart.

In the strength of materials, a bending moment is the reaction that occurs in a structural element when an external force is applied and causes the element to bend. It’s the internal resistance of a structure to bending.

Bending Stress

A beam is a structural member that is subjected to loads acting in transverse direction due to which internal actions, or stresses, in the form of bending moments and shear forces are produced. Bending moment produces bending stresses that are normal to cross-section of beam while shear force produces shears stresses.

Shear Stress

Shear stress is a measure of how much force a material can withstand before it deforms or breaks when force is applied parallel to its surface. It’s also known as tangential stress.

Torsion of Circular Shafts

Torsion of a circular shaft is the twisting distortion that occurs when a shaft is fixed at one end and a torque is applied perpendicular to its axis. The shaft will bend without changing its cross-section

Column

A compression member is a structural member which is straight and subjected to two equal and opposite compressive forces applied at its ends. It may be vertical (column) and inclined (strut). Column is a compression member subjected to predominantly axial loading. There are three modes of failure of columns:

- Crushing (yielding): Generally short column fails in this mode.

- Buckling (elastic instability): Generally long column fails in elastic bending i.e., buckling or elastic instability.

- Combined crushing and buckling: This is the common case of intermediate column.

Online Courses for Strength of Material Systems (CE):

Candidates pursuing civil engineering can see high competition while preparing for government engineering exams such as GATE, ESE, SSC JE and many others. While government jobs bring along a stable career and job security, it is not easier to crack the exam. Such exams expect hard work, dedication and a well strategic planning and study routine. MADE EASY is here to support your preparation journey of GATE, ESE and PSU exams. Our courses are curated by renowned experts that focus on providing quality lectures from the basic level to advanced level. MADE EASY provides aspirants the right guidance to maximize their performance and achieve success. Civil engineering candidates are advised to visit on the links given below to know more about courses that include key concepts of engineering branches taught from basic level and prepare aspirants for the future.

- GATE : 1 Year Foundation Course

- ESE+GATE : 1 Year Foundation Course

- GATE + SES (GS) : 1 Year Foundation Course

- GATE & SES (GS) 2025-26 Live Online Foundation Course

- ESE + GATE + SES (GS) 2025-26 Live Online Foundation Courses

Recommended Books for Strength of Material Systems

Books are still an essential part of learning as they offer in-depth knowledge in various topics. Learning books are well structured and provide comprehensive understanding making them invaluable for students and lifelong learners. MADE EASY Publications is one such platform for students who are looking for high quality and well structured content for their preparation. Our platform consists of government engineering exams books which are curated by a team of experts and experienced authors. Civil engineering aspirants are suggested to click on the links mentioned below to learn more in depth about strength of materials:

- A Self-Study Guide for Strength of Materials

- GATE-2025: Civil Engineering Previous Year Solved Papers

- ESE 2025: Preliminary Exam: Civil Engineering Objective Solved Paper Vol-1

- A Handbook on Civil Engineering

Learn in detail about the concept of stress from B. Singh Sir.

1. Basic Concepts of Strength of Materials (Lecture – 1) | Stress

2. Basics of Strength of Materials(Lecture-2):Stress Strain & Elasticity

MADE EASY faculty have briefly explained the strength of materials. Click on the given links to learn more about.

Frequently Asked Questions (FAQs):

1. What is the basic definition of SOM?

Ans. Strength of material is a branch of applied mechanics that deals with the behavior of solid bodies subjected to various types of loading and internal forces developed due to these loading. A thorough understanding of mechanical behaviour is essential for the safe design of all structures, whether buildings, bridges, machines, motors, submarines or airplanes. Hence, strength of materials is a basic subject in many engineering fields.

2. What is strength and stiffness?

Ans. Strength and stiffness are physical properties of a material that measure how it responds to stress:

- Strength

The maximum stress a material can withstand before it deforms permanently or fractures. Strength is measured in N/m2. - Stiffness

A material’s resistance to bending or deformation. Stiffness is measured in N/m.

3. What is strain?

Ans. Strain is defined as the change in dimension with respect to the original dimension.

4. What symbol is stress?

Ans. The symbol for stress is (σ).