Air Compressor in Power Plant

An air compressor is a machine which takes in atmospheric air, compresses it with the help of some mechanical energy and delivers it at higher pressure. An air compressor increases the pressure of air by decreasing its specific volume using mechanical means. Thus compressed air carries an immense potential of energy. The controlled expansion of compressed air provides motive force in air motors, pneumatic hammers, air drills, sand-blasting machines and paint sprayers, etc. It is also called air pump.

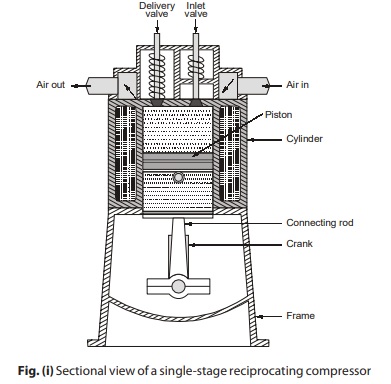

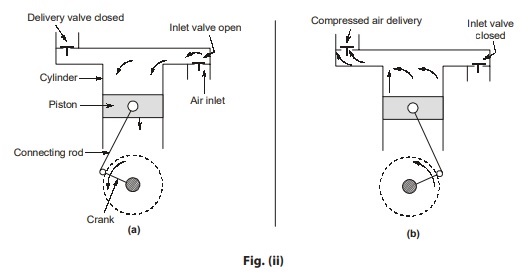

- Construction and working principal of reciprocating compressor (single stage) is shown in Fig. (i) and (ii) respectively.

- Compression pressure of this type of compressor can be very high and is limited by strength of various parts of compressor and the power of driving motor.

- In reciprocating air compressor, air flow is intermittent and not continuous like centrifugal and axial flow compressors.

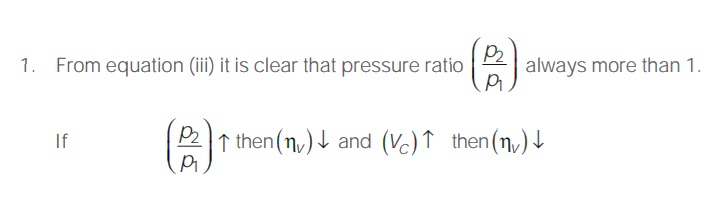

i.e. If pressure ratio and clearance volume increases, in both the cases volumetric efficiency will decrease.

i.e. If pressure ratio and clearance volume increases, in both the cases volumetric efficiency will decrease.

2. Volumetric efficiency is lowered due to following reason:

-

- Increase in pressure ratio

- Increase in clearance volume

- Very high speed

- Obstruction in inlet valve

- Overheating of air by contact with hot cylinder walls

- Inertia effect of air in suction pipe

Advantages of Multistage Compression

- High volumetric efficiency: Intercooling between the stages improve the volumetric efficiency.

- Reduced driving power: Due to intercooling, work input for compression is reduced.

- Better mechanical balance and uniform torque: is achieved with multi stage compression.

- Size and strength of cylinders can be adjusted according to the volume and pressure of gas.

- Lubrication difficulties and explosion hazard are reduced because maximum temperature reached during the compression process is greatly reduced.

- Leakages losses are reduced considerably.

<< Previous | Next >>

Must Read: What is Power Plant Engineering?

Dear Aspirants,

Your preparation for GATE, ESE, PSUs, and AE/JE is now smarter than ever — thanks to the MADE EASY YouTube channel.

This is not just a channel, but a complete strategy for success, where you get toppers strategies, PYQ–GTQ discussions, current affairs updates, and important job-related information, all delivered by the country’s best teachers and industry experts.

If you also want to stay one step ahead in the race to success, subscribe to MADE EASY on YouTube and stay connected with us on social media.

MADE EASY — where preparation happens with confidence.

MADE EASY is a well-organized institute, complete in all aspects, and provides quality guidance for both written and personality tests. MADE EASY has produced top-ranked students in ESE, GATE, and various public sector exams. The publishing team regularly writes exam-related blogs based on conversations with the faculty, helping students prepare effectively for their exams.