Types of Riveted Joints

Material of Rivets

The material of the rivets must be tough and ductile. They are usually made of steel, brass, aluminium, but when strength and fluid tight joint is the main consideration then the steel rivets are used.

Rivet Heads

The snap heads are usually employed for structural work and machine riveting. The counter sunk heads are mainly used for ship building where flush surfaces are necessary. The conical heads are mainly used in case of hand hammering. The pan heads have maximum strength, but these are difficult to shape.

Types of Riveted Joints

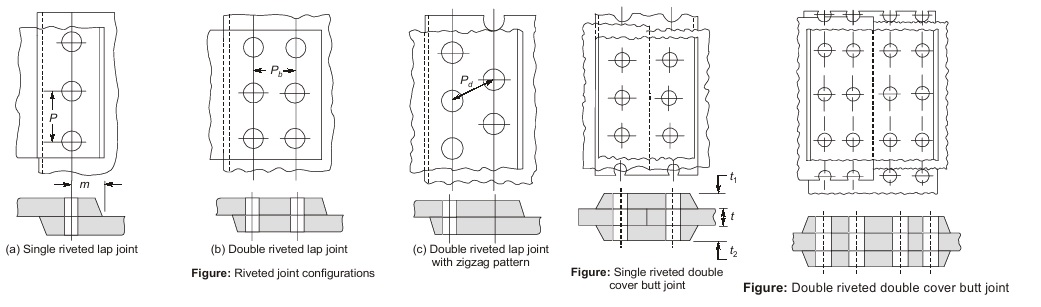

Lap Joint: A lap joint is that in which one plate overlaps the other and the two plates are then riveted together.

Butt Joint: A butt joint is that in which the main plates are kept in alignment butting (i.e. touching) each other and a cover plate is placed either on nose side or on both sides of the main plates.

A single riveted joint is that in which there is a single row of rivets in a lap joint and there is a single row of rivets on each side in a butt joint.

A double riveted joint is that in which there are two rows of rivets in a lap joint and there are two rows of rivets on each side in a butt joint.

- When the rivets in the various rows are opposite to each other then the joint is said to be chain riveted.

- If the rivets in the adjacent rows are staggered in such a way that every rivet is in the middle of the two rivets of the opposite row then the joint is said to be zig-zag riveted.

- Since the plates overlaps in lap joints, therefore the forces P, acting on the plates are not in the same straight line but they are at a distance equal to the thickness of the plate.

These forces will form a couple which may bend the joint. Hence the lap joints may be used only where small loads are to be carried. But in the butt joints there will be no couples; hence, butt joints are used where heavy loads are to be carried.

<< Previous | Next >>

Must Read: What is Machine Design?

Dear Aspirants,

Your preparation for GATE, ESE, PSUs, and AE/JE is now smarter than ever — thanks to the MADE EASY YouTube channel.

This is not just a channel, but a complete strategy for success, where you get toppers strategies, PYQ–GTQ discussions, current affairs updates, and important job-related information, all delivered by the country’s best teachers and industry experts.

If you also want to stay one step ahead in the race to success, subscribe to MADE EASY on YouTube and stay connected with us on social media.

MADE EASY — where preparation happens with confidence.

MADE EASY is a well-organized institute, complete in all aspects, and provides quality guidance for both written and personality tests. MADE EASY has produced top-ranked students in ESE, GATE, and various public sector exams. The publishing team regularly writes exam-related blogs based on conversations with the faculty, helping students prepare effectively for their exams.