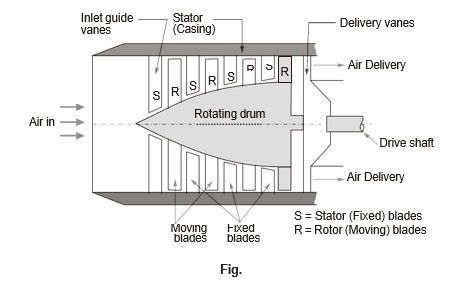

What is Axial Flow Compressor?

The axial flow compressors are used in the gas turbine power plant and especially in aircraft applications.

- Disc type rotor For aircraft applications Low weight but high cost.

- Drum type rotor For static industrial application High weight but low value.

- Fluid flow proceed, throughout the compressor in a direction parallel to the axis of the machine.

- Air approaches the rotor blades with absolute velocity V1 and at an angle α1. The relative velocity Vr1, obtained by the vectorial addition of absolute velocity V1 and blade velocity u has the inclination β1 with the axial direction.

- Flow velocity remains constant throughout the compressor length because annular area is usually reduced from inlet to outlet of the compressor.

- In diverging section: There is rise in temperature due to diffusion action. Absolute velocity is also increased due to work input.

Function of Fixed Blades

- It converts a part of K.E. of the flowing fluid into pressure energy by diffusion process.

- By guiding and redirecting the flowing fluid, ensures that the entry of the fluid to the next stage is without shock.

Surging and Stalling

- Unstable flow in axial compressors can be due to two reasons:

- The separation of flow from the blade surfaces called stalling.

- Complete breakdown of the steady through flow called surging.

Both these phenomenon occur due to off design conditions of operation and are aerodynamically and mechanically undersirable.

- Surging affects the whole machine while stalling is a local phenomenon.

- At large values of incidence, flow separation occurs on the suction side of the blades which is referred as positive stalling.

- Negative stall is due to the separation of flow occurring on the pressure side of the blade due to large values of negative incidence.

- Blades are said to be ‘stalled’ when the air stream fail to follow the blade contour.

- Design of blades should be based on aerodynamic theory so that wasteful losses due to shock and turbulence are prevented and blades are free from stalling trouble.

<< Previous | Next >>

Must Read: What is Power Plant Engineering?

WhatsApp Group

Join Now

Telegram Group

Join Now