What are the characteristics of a Fan Curve?

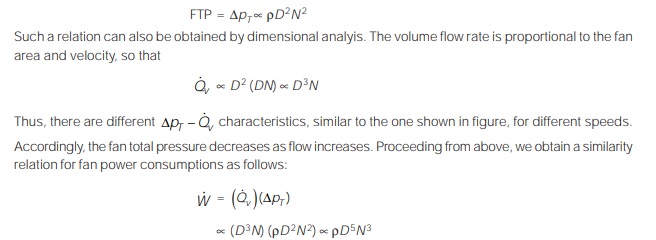

Fan characteristics can be represented in form of fan curve(s). The fan curve is a performance curve for the particular fan under a specific set of conditions. The fan curve is a graphical representation of a number of inter- related parameters. Typically a curve will be developed for a given set of conditions usually including: fan volume, system static pressure, fan speed, and brake horsepower required to drive the fan under the stated conditions. Some fan curves will also include an efficiency curve so that a system designer will know where on that curve the fan will be operating under the chosen conditions (see Figure). In the many curves shown in the Figure, the curve static pressure (SP) vs. flow is especially important.

The intersection of the system curve and the static pressure curve defines the operating point. When the system resistance changes, the operating point also changes. Once the operating point is fixed, the power required could be found by following a vertical line that passes through the operating point to an intersection with the power (BHP) curve. A horizontal line drawn through the intersection with the power curve will lead to the required power on the right vertical axis. In the depicted curves, the fan efficiency curve is also presented.

The required fan work can be calculated by knowing the flow rate and fan total pressure and including the fan efficiency in it. Thus

Classification of Boilers

- Fire tube boiler : In the fire tube boilers; the hot gases are inside the tubes and water surrounds the Example Cochran, Lancashire, Locomotive etc.

- Water tube boiler: In the water tube boilers, the water is inside the tubes and hot gas surrounds them. Example Babcock and Wilcox, Stirling, Yarrow boiler etc.

- Externally fired boiler: In the externally fired boiler fire is outside the shell. Example Babcock and Wilcox boiler, Stirling boiler etc.

- Internally fired boiler: In case of internally fired boilers, the furnace is located inside the boiler shell Example Cochran, Lancashire boiler etc.

- Forced circulation boiler: In forced circulation, circulation of water is done by a pump. Example Velox, Lamont, Benson etc.

- Natural circulation boiler: In natural circulation type of boiler water in boilers takes place due to natural convection currents. Example Lancashire, Babcock & Wilcox etc.

- Super critical boiler: The boiler which operating parameter is above critical point which is p = 221.2 bar and T = 373°C, is called super-critical boiler.

Boiler Mounting

- The item which is used for safety of boiler is called boiler mounting.

- The items such as stop valve, safety valves, fusible plug, blow off cock, pressure gauges, water level indicator.

Boiler Accessories

- The item which is used to increase the efficiency of boiler is called boiler accessories.

- The items such as superheaters, economizers, feed pumps etc. are termed as accessories, they form integral part of boiler.

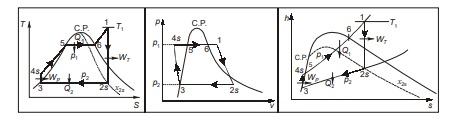

Analysis of Steam/Rankine Cycle with Superheating

|

Process 4s-1 : |

Reversible constant pressure heating of water (Q1) in boiler |

|

Process 1-2s : |

Reversible adiabatic expansion of steam in turbine (WT) |

|

Process 2s-3 : |

Reversible constant pressure heat rejection (Q2) in condenser |

| Process 3-4s : |

Reversible adiabatic input work (WP) in pump. |

For 1 kg of fluid, the steady flow energy equation to each processes:

|

Process |

Component | Reduced SFEE |

|

1 – 2s |

Turbine | WT = h1 – h2s |

|

2s – 3 |

Condenser |

Q2 = h2s – h3 |

|

3 – 4s |

Pump |

WP = h4s – h3 |

| 4s – 1 | Boiler |

Q1 = h1 – h4s |

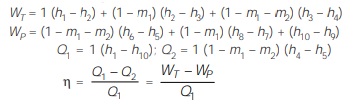

- Efficiency of Rankine cycle (Ideal)

![]()

Mean Temperature of Heat Addition

In the Rankine cycle, heat is added reversible at a constant pressure but at infinite temperatures. If Tm is the mean temperature of heat addition then

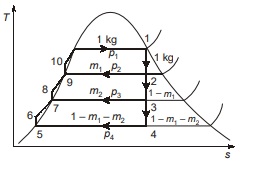

Regenerative Feed Water Heating

In practical regenerative cycle the feed water enters the boiler at high temperature as compared to the corresponding temperature in case of simple Rankine cycle and it is heated by steam extracted or bled from intermediate stages of the turbine.

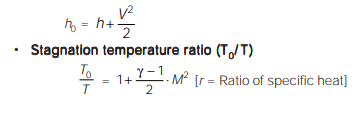

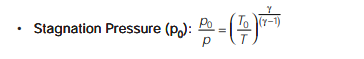

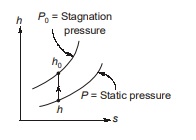

Stagnation Properties

It is defined as the state a fluid in motion would reach if it is brought to rest isentropically in steady flow and zero work output device.

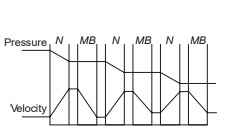

Pressure compounding

where, N = Nozzle,

MB = Moving blade

The pressure drop occur only in nozzle. There is no pressure drop while steam flows through the blades.

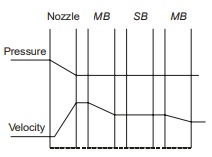

Velocity compounding Nozzle

where, SB = Stationary blade

All the pressure drop and enthalpy drop of steam takes place in a single row of nozzles.

<< Previous | Next >>

Must Read: What is Power Plant Engineering?

Dear Aspirants,

Your preparation for GATE, ESE, PSUs, and AE/JE is now smarter than ever — thanks to the MADE EASY YouTube channel.

This is not just a channel, but a complete strategy for success, where you get toppers strategies, PYQ–GTQ discussions, current affairs updates, and important job-related information, all delivered by the country’s best teachers and industry experts.

If you also want to stay one step ahead in the race to success, subscribe to MADE EASY on YouTube and stay connected with us on social media.

MADE EASY — where preparation happens with confidence.

MADE EASY is a well-organized institute, complete in all aspects, and provides quality guidance for both written and personality tests. MADE EASY has produced top-ranked students in ESE, GATE, and various public sector exams. The publishing team regularly writes exam-related blogs based on conversations with the faculty, helping students prepare effectively for their exams.