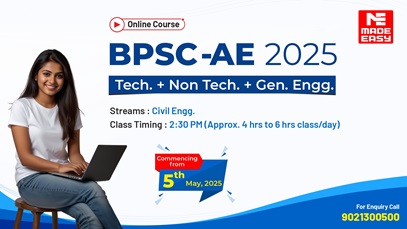

Actual P-V Diagram for Single-Stage Compressor

Theoretical p-V diagram – (1-2-3-4)

Theoretical inlet valve should open at point ‘4’ but in practice it is not opening at point ‘4’, due to the following two main reasons:

- Pressure difference is required across the inlet valve in order to move it.

- Inlet valve inertia

- So negative pressure difference is required to open the valve and called as intake depression.

- Similar situation occurs at 2, at the beginning of delivery stroke. Compressed air is delivered into receiver and hence external delivery pressure is also known as receiver pressure.

- Gas inertia and turbulence also affecting the inlet and delivery.

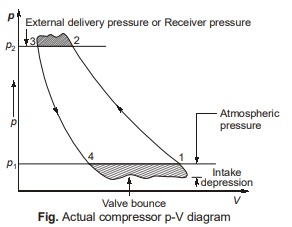

Actual p-V Diagram of for Two Stage Compressor

- Inertia and friction effects, which results in valve flattering and increase the area of diagram slightly and hence their effects is to increase the total work of compression.

- LP and HP diagram overlap due to pressure drop in intercooler.

- Wavy lines during induction and delivery strokes are due to “Flatter” of valve’s disc.

Reciprocating Compressors

- Greater vibration problem.

- Mechanical efficiency is lower compare to rotary compressor because of several sliding and bearing members.

- Pressure ratio per state is 5 to 8.

- Delivery volume is small (250 – 300 m3/min) compared to rotary compressor (2000 – 3000 m3/min).

- Compression efficiency is high at compression ratio above 2.

- Reciprocating air compressors are having isothermal compression where as Rotary air compressors are having isentropic compression.

<< Previous | Next >>

Must Read: What is Power Plant Engineering?

WhatsApp Group

Join Now

Telegram Group

Join Now