Strength of Welded Joints

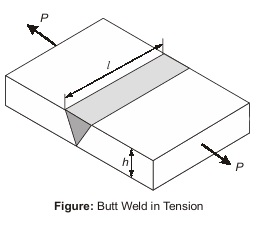

(i) Strength of Butt Weld

A butt welded joint, subjected to tensile force P, is shown in given figure.

Here,

σt = Tensile stress in weld

P = Tensile force on the plates (N)

h = Throat of Butt weld

t = Thickness of plate

l = Length of weld

σt = P/hl

Because reinforcement is provided to compensate for flaws in the weld, equating throat of the weld ‘h’ to the plate thickness ‘t’.

σt = p/lt

For safety, there must be reduction in strength of a butt welded joint by a factor called “Efficiency of Joint”.

P = η σt t l

η = Efficiency of welded joint

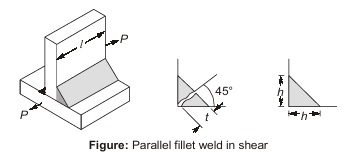

(ii) Strength of Parallel Fillet Joint

A parallel fillet weld subjected to a tensile force P is shown below.

h = Leg of weld (size of weld)

t = Throat (it is the minimum cross-section of weld at 45° to leg)

l = Length of weld

t = h cos (45°)

t = 0.707 h (for right-angle triangle with two equal side)

Generally the leg length ‘h’ is equal to the plate thickness.Because failure of the fillet weld occurs due to shear along the minimum cross-section of the weld.

Permissible shear stress, τmax = P/tl = P/ 0.707hl

If there are two welds of equal length on two equal side of vertical plate.

τmax = P/ 1.414hl

As per American Welding Society (AWS), permissible shear stress for fillet weld is 94 N/mm2 in case of static load.

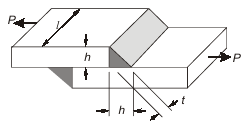

(iii) Strength of Transverse Fillet Weld

A transverse fillet weld subjected to a tensile force P is given below

This weld is subjected to tensile stress and failure will occur at minimum cross-section of weld at throat.

Permissible tensile stress, σt =P/tl = P/ 0.707hl

If there are weld of equal length σt =P/ 1.414hl

<< Previous | Next >>

Must Read: What is Machine Design?

Dear Aspirants,

Your preparation for GATE, ESE, PSUs, and AE/JE is now smarter than ever — thanks to the MADE EASY YouTube channel.

This is not just a channel, but a complete strategy for success, where you get toppers strategies, PYQ–GTQ discussions, current affairs updates, and important job-related information, all delivered by the country’s best teachers and industry experts.

If you also want to stay one step ahead in the race to success, subscribe to MADE EASY on YouTube and stay connected with us on social media.

MADE EASY — where preparation happens with confidence.

MADE EASY is a well-organized institute, complete in all aspects, and provides quality guidance for both written and personality tests. MADE EASY has produced top-ranked students in ESE, GATE, and various public sector exams. The publishing team regularly writes exam-related blogs based on conversations with the faculty, helping students prepare effectively for their exams.