Caulking and Fullering

Important Terms Used in Riveted Joint

- Pitch: It is the distance from the centre of one rivet to the centre of the next rivet measured parallel to the seam.

- Back Pitch: It is perpendicular distance between the centre lines of the successive rows.

- Diagonal Pitch: It is the distance between the centres of rivets in adjacent rows of zig-zag riveted joint.

- Margin and Marginal Pitch: It is the distance between the centre of rivet hole to the nearest edge of the plate.

Caulking and Fullering

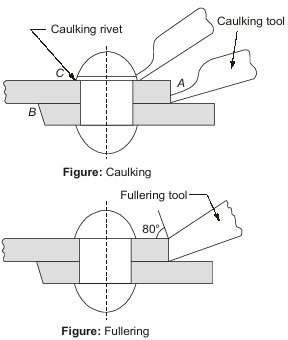

In order to make the joints leak proof or fluid tight in pressure vessels like steam boilers, air receivers and tanks etc. a process known as caulking is employed. In this process a narrow blunt tool called caulking tool is used. Firstly edges of plate in lap joint and edges of strap plate in butt joint are beveled to 70° to 75° and then tool is hammared on edge.

A more satisfactory way of making the joints staunch is known as fullering which has largely super sided caulking. In this case a fullering tool with a thickness at the end equal to that of the plate is used in such a way that the greatest pressure due to the blows occur near the joint, giving a clean finish with less risk of damaging the plate.

<< Previous | Next >>

Must Read: What is Machine Design?

Dear Aspirants,

Your preparation for GATE, ESE, PSUs, and AE/JE is now smarter than ever — thanks to the MADE EASY YouTube channel.

This is not just a channel, but a complete strategy for success, where you get toppers strategies, PYQ–GTQ discussions, current affairs updates, and important job-related information, all delivered by the country’s best teachers and industry experts.

If you also want to stay one step ahead in the race to success, subscribe to MADE EASY on YouTube and stay connected with us on social media.

MADE EASY — where preparation happens with confidence.

MADE EASY is a well-organized institute, complete in all aspects, and provides quality guidance for both written and personality tests. MADE EASY has produced top-ranked students in ESE, GATE, and various public sector exams. The publishing team regularly writes exam-related blogs based on conversations with the faculty, helping students prepare effectively for their exams.