TYPES OF STEPPER MOTORS

Variable-Reluctance Stepper Motors

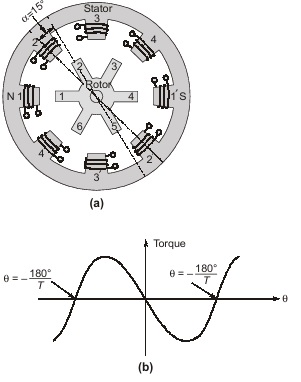

A variable-reluctance stepper motor consists of a single or several stacks of stators and rotors. Stators have a common frame and rotors have a common shaft. The stator and rotor teeth are of same number and size and therefore can be aligned as shown in fig. (a).

The stators are pulse excited, while the rotors are unexcited. The static torque acting on the rotor is a function of the angular misalignment θ.

There are two positions of zero torque :

(i) θ = 0, rotor and stator teeth aligned

(ii) θ = 360°/2T = 180° /T (where T = no. of rotor teeth) rotor teeth aligned with stator slots.

- The shape of the static torque-angle curve of one stack of a stepper motor is shown in fig. (b).

It is nearly sinusoidal.

Teeth aligned at θ = 0 is a stable position.

Teeth aligned at θ = 180°/T is unstable.

Thus rotor locks into stator in position θ = 0 multiple of 360°/T. With the teeth on all the rotors are perfectly aligned, stator teeth of various stacks differ by an angular displacement of

α= 360°/nT

where, n=no. of stacks

Directional control is possible with three or more phases.

Permanent Magnet Motor

These stepper motor has permanent-magnet rotor. The rotor is made of ferrite or rare-earth material which is permanently magnetised. The rotor move in steps of 22 1°/2. Compared to variable-reluctance motors, permanent

magnet stepper motors operate at larger steps up to 90° and at maximum response rates of 300 pulse per second (pps).

Hybrid Stepper Motor

This is a permanent magnet stepper motor with toothed and stacked rotor of variable-reluctance motor. The stator has only one set of winding excited poles which interact with the two rotor stacks. The two sets of teeth are displaced from each other by one half of the tooth pitch also called pole pitch. After removal of excitation, the rotor will continue to remain locked into the same position as it is prevented to move in either direction by torque because of the permanent magnet excitation.

Compared to PM motor finers steps for better resolution are obtained in hybrid motor by increasing the number of stack teeth and also by adding additional stack pans on the rotor. As compared to variable-reluctance motor a hybrid motor requires less stator excitation current because of the PM excited rotor. Microstepping is possible in hybrid motors. Step sizes are 15°, 7.5°, 2° and 0.72°.

Dear Aspirants,

Your preparation for GATE, ESE, PSUs, and AE/JE is now smarter than ever — thanks to the MADE EASY YouTube channel.

This is not just a channel, but a complete strategy for success, where you get toppers strategies, PYQ–GTQ discussions, current affairs updates, and important job-related information, all delivered by the country’s best teachers and industry experts.

If you also want to stay one step ahead in the race to success, subscribe to MADE EASY on YouTube and stay connected with us on social media.

MADE EASY — where preparation happens with confidence.

MADE EASY is a well-organized institute, complete in all aspects, and provides quality guidance for both written and personality tests. MADE EASY has produced top-ranked students in ESE, GATE, and various public sector exams. The publishing team regularly writes exam-related blogs based on conversations with the faculty, helping students prepare effectively for their exams.