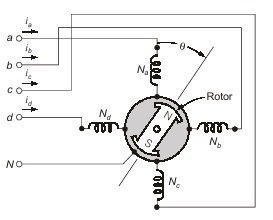

STEPPER MOTORS

The stepper motor is a special type of synchronous motor which is designed to rotate through a specific angle called a step for each electrical pulse received by its control unit. The step sizes are 7.5°, 15° or larger. The step motor is used in digitally controlled position control system in open-loop mode. The input command is in the form of a train of pulses to turn a shaft through a specified angle.

Advantages

- Compatible with digital systems.

- No sensors are needed for position and speed sensing as these are directly obtained by counting input pulses and periodic counting input pulses, if speed information is needed.

Application

- As paper feed motors in type writers and printers, positioning of print heads, pens in XY-plotters, recording heads in computer disk drives and in positioning of work tables and tools in numerically controlled machine equipment. The range of these motors is increasing as these motors are becoming available in larger power ratings and with reducing cost.

- Elementary operation of a four-phase stepper motor with a two-pole rotor is illustrated above in figure.

Dear Aspirants,

Your preparation for GATE, ESE, PSUs, and AE/JE is now smarter than ever — thanks to the MADE EASY YouTube channel.

This is not just a channel, but a complete strategy for success, where you get toppers strategies, PYQ–GTQ discussions, current affairs updates, and important job-related information, all delivered by the country’s best teachers and industry experts.

If you also want to stay one step ahead in the race to success, subscribe to MADE EASY on YouTube and stay connected with us on social media.

MADE EASY — where preparation happens with confidence.

MADE EASY is a well-organized institute, complete in all aspects, and provides quality guidance for both written and personality tests. MADE EASY has produced top-ranked students in ESE, GATE, and various public sector exams. The publishing team regularly writes exam-related blogs based on conversations with the faculty, helping students prepare effectively for their exams.