Excitation Systems for Synchronous Machines

Definition :-

The system which provides DC to the synchronous machine field winding to perform protective and control function of the power system is known as excitation systems. This system consists of exciter, Power System Stabiliser (PSS), Automatic Voltage Regulator (AVR), processing unit and measuring elements. The current provided by the system is excitation current. Excitation means production of flux by passing current in field winding.

Types of Excitation System

1. DC Excitation System : The DC excitation system consists of two types of exciters, they are main exciter and pilot exciter. The exciter output is adjusted by the AVR to control the alternator output terminal voltage. These two exciters can be driven either by motor or by main shaft.

Advantages :

• Compact in size

• More reliable

Disadvantages :

• Response is slow.

• Voltage regulation is complex.

2. AC Excitation System : The AC excitation system consists of a thyristor rectifier bridge and alternator which are connected directly to the main shaft. AC excitation system is of two types :

(a) Rotating Thyristor excitation System : The rotating portion of the rotating thyristor excitation system consists of alternator field rectifier, rectifier circuit, power supply and an AC exciter.

Advantages :

• Low cost

• Simple to construct

Disadvantages :

• Response rate of thyristor is very low.

(b) Brushless Excitation : The main components of brushless alternator system are the stator and the rotor. The stator body consists of the main stator and an exciter stator. Similarly the rotor assembly consists of the main rotor and the exciter rotor along with a bridge rectifier assembly mounted on a plate that is attached to the rotor. The exciter stator has residual magnetism when the rotor starts rotating AC output is generated in the exciter rotor coils and this output is passed through a bridge rectifier. The output passed through a bridge rectifier is converted into DC and given to the main rotor. The moving main rotor generates AC in the stationary main rotor coils.

Advantages :

• Systems response is good.

• Reliable type of excitation system.

• Maintenance is low because there is no moving contact in the brushless system.

Disadvantage :

• Slow de-excitation

(iii) Static Excitation System : Static excitation system consists of rectifiers, transformers, SCR output stage, excitation start-up, field discharge equipment etc. In this system, there is no rotating part, so there is no windage losses and no rotational losses.

Advantages :

• Low losses.

• Response and reliability is good.

Disadvantages :

• It requires slip ring and brush arrangement.

• In smaller machines, DC is supplied to the rotor field by a DC generator called exciter. This exciter may be supplied current by a smaller DC generator called pilot exciter.

• For medium sized machines, AC exciters are used in place of DC exciters.

• For large synchronous machines with high rating (in megawatt), the excitation requirements becomes very large so brushless excitation system is used.

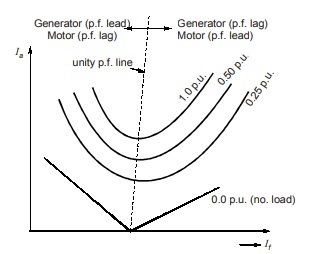

V-Curve

V-curve is the plot of Ia vs. If at constant load while the Vt remains constant.

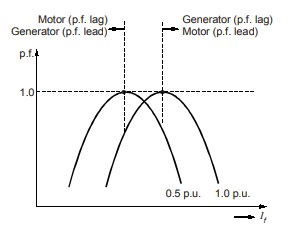

Inverted V-Curve

Inverted V-Curve is the plot of power factor (p.f.) vs If.

Applications of Synchronous Motors

Synchronous motors were mainly used in constant speed applications. The development of semiconductor variable frequency sources, such as inverters and cyclo-converters, has allowed their use in variable speed applications such as high power and high speed compressors, blowers, induced and forced draft fans, mainline traction, servo drives, etc.

Since a synchronous condenser behaves like a variables inductor or a variable capacitor, it is used in power transmission systems to regulate line voltage. In industry, synchronous motors are used with induction motors and operated with over excitation to draw leading current from the supply. Thus, they compensate the lagging current drawn by the induction motors to improve the overall power factor of the plant.

Dear Aspirants,

Your preparation for GATE, ESE, PSUs, and AE/JE is now smarter than ever — thanks to the MADE EASY YouTube channel.

This is not just a channel, but a complete strategy for success, where you get toppers strategies, PYQ–GTQ discussions, current affairs updates, and important job-related information, all delivered by the country’s best teachers and industry experts.

If you also want to stay one step ahead in the race to success, subscribe to MADE EASY on YouTube and stay connected with us on social media.

MADE EASY — where preparation happens with confidence.

MADE EASY is a well-organized institute, complete in all aspects, and provides quality guidance for both written and personality tests. MADE EASY has produced top-ranked students in ESE, GATE, and various public sector exams. The publishing team regularly writes exam-related blogs based on conversations with the faculty, helping students prepare effectively for their exams.