Sewage Discharge

ESTIMATION OF SEWAGE DISCHARGE

The sewage discharge which has to pass through a sewer must be estimated as correctly as possible. Otherwise, the sewers may either prove to be inadequate, resulting in the overflow, or may prove to be of too much of size, resulting in unnecessary investments or uneconomical.

The quantity of sewage through a sewer (Q′) at end of its design period can be computed by multiplying per capita production of sewage (q ′) by expected population at end of design period.

The per capita sewage which is produced (q ′) in a community can be estimated by assuming it as 75 to 85 percent of per capita water supplied (q). The per capita demand of water (q) and corresponding per capita sewage production (q ′) is based upon annual flows, and therefore are defined as annual average daily flow per person. Although this average value is useful but it not sufficient for designing of various components of a sewerage scheme, because there are wide variations in actual flows that takes place through sewers at any given time.

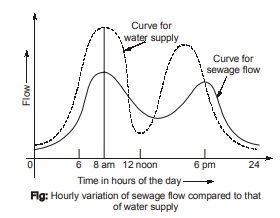

Although the flow in sanitary sewers fluctuate seasonally, monthly, daily as well as hourly with water consumption, yet they are sometimes delayed and less pronounced as they are damped because of storage space in sewers and time required for sewage to reach the gauging point.

It can be seen in figure that peak for sewerage flow are dampened because it requires considerable sewage to fill the sewers to high flow point and high flows from various sections will reach the gauging point after different time of flows. Thus, the time when peak flow occurs will depend upon flow time in sewers. If the sewage is gauged near its origin, peak flow will be more pronounced whereas if the sewage has to travel a long distance before gauged, the peak will be dampened. Hence, peak flows (expressed as number of times of their average values) will be much greater for small lateral sewers, as compared to these for large trunk sewers.

For areas of moderate sizes, such as for branched sewers, maximum daily or hourly sewage flows can be expressed as

Maximum daily flow = 2 times the average daily flow

Maximum hourly flow = 1.5 times the maximum daily flow = 3 times the average daily flow

The estimation of maximum hourly flows for different types of sewers is given in the table below.

| Hourly variations in sewage flow | ||

|---|---|---|

| S. No. | Type of sewer | Ratio of maximum flow to average flow |

|

1. 2. 3. 4. |

Trunk mains above 1.25 m in dia.

Mains up to 1 m in dia. Branches up to 0.5 m in dia. Laterals and small sewers upto 0.25 m in dia. |

1.5 20. 3.0 4.0 |

The minimum flow passing through a sewer is an important factor in design of sewer, because if the flow is very low, then the velocity will be low and hence silting will take place. Hence, the slope at which the sewer is to be laid has to be decided in accordance with requirement of minimum permissible velocity at minimum flow.

For moderate areas, for designing of branch sewers, the following minimum flow may be assumed.

Minimum daily flow = 2/3 x Average daily flow

Minimum hourly flow = 1/2 x Minimum daily flow

Minimum hourly flow = 1/3 x Average daily flow

The sewers, must therefore be checked minimum velocities at their minimum hourly flows.

Asbestos cement sewers

Asbestos cement pipes are manufactured from a mixture of asbestos fibre, silica and cement, converted under pressure to a dense homogeneous materials, possessing considerable strength, called asbestos cement. The asbestos fibre which is thoroughly mixed with cement serves as reinforcement, and provides a strong material. These pipe are normally available in sizes say from 10 to 90 cm in diameter and 4 metres in length.

Joining:

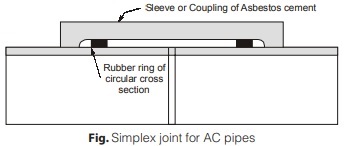

These pipes can be easily assembled without skilled labour, with the help of a special coupling (called Ring Tie coupling or Simplex joint) as shown in figure. The assembly consists of a pipe sleeve and two rubber rings, which are compressed between the pipe and the interior of the sleeve. The joint is resistant to corrosion as the pipe itself, and is flexible enough as to permit as much as 12° deflection, while laying the pipes around curves (in plan).

The advantages of AC pipes are:

- They are light in weight and hence easy to transport.

- They can be easily cut and assembled without skilled labour.

- Their interior surface is exceptionally smooth (with Manning’s N = 0.011), thus providing an excellent hydraulically efficient sewer.

The disadvantages of AC pipe are:

- They are structurally not strong enough to bear the huge compressive stresses induced by the heavy external loads to which the deeply buried sewers may be subjected.

- They are susceptible to corrosion by sulphuric acid from hydrogen sulphide gas generated in sanitary wastewater or by some industrial chemicals. The sulphide corrosion of asbestos cement as well as cement concrete pipes is a big problem in areas where the sewage is strong, stale, and very warm, because under such conditions the bacterial activity responsible for producing hydrogen sulphide gas gets accelerated. Hence, in all such cases, vitrified clay (popularly called stoneware) pipes should be used for sewers of less than 1 m in diameter, and cement concrete pipes with cast in situ plastic linings may be used for larger diameter sewers.

CORROSION OF CONCRETE SEWERS

- H2S in sewer is usually produced by bacteriological reduction of sulphates.

- H2S gas by itself is not injurious to cement concrete. It gets readily oxidsed by dissolved oxygen or by several bacterial species.

- In the presence of air, H2S gets oxidised to H2SO4 and this sulphuric acids reacts with the cement constituents of concrete.

- Actually, it reacts with the lime in the cement concrete to form CaSO4 which in turn, reacts with the calcium aluminates in the cement to form calcium sulpho-aluminates which occupy a greater volume than the compound they replace. This leads to expansion and disruption of concrete sewer.

<< Previous | Next >>

Must Read: What is Environmental Engineering?

Dear Aspirants,

Your preparation for GATE, ESE, PSUs, and AE/JE is now smarter than ever — thanks to the MADE EASY YouTube channel.

This is not just a channel, but a complete strategy for success, where you get toppers strategies, PYQ–GTQ discussions, current affairs updates, and important job-related information, all delivered by the country’s best teachers and industry experts.

If you also want to stay one step ahead in the race to success, subscribe to MADE EASY on YouTube and stay connected with us on social media.

MADE EASY — where preparation happens with confidence.

MADE EASY is a well-organized institute, complete in all aspects, and provides quality guidance for both written and personality tests. MADE EASY has produced top-ranked students in ESE, GATE, and various public sector exams. The publishing team regularly writes exam-related blogs based on conversations with the faculty, helping students prepare effectively for their exams.