Rapid Hardening Cement (RHC)

- It is finer than ordinary Portland cement.

- It contains more C3S (> 56%) and less C2S than the OPC.

- 1 day strength ≃ 16 N/mm2 (3 days strength of OPC 33) and 3 days strength ≃ 22 N/mm2 (7 days strength of OPC 33).

- The main advantage of rapid hardening cement is that shuttering may be removed much earlier, thus saving considerable time and expenses.

- Rapid hardening cement is also used for road work where it is imperative to open the road traffic with the minimum delay.

- Cost of Rapid hardening cement is nearly 10–15% more than OPC.

- It can be safely exposed to frost as it matures more quickly.

- Initial and final setting time is same as that of OPC.

- Owing to the high amount of C3S, heat of hydration is more and hence more shrinkage cracks are formed.

Super Sulphated Cement (SSC)

- It is made from well granulated blast furnace slag (80-85%), calcium sulphate (10-15%) and Portland cement (1-2%) and is ground finer than the Portland cement (about 4000 cm2/gm).

- In this cement C3A, which is susceptible to sulphates is limited to less than 3.5%.

- Sulphate resisting cement can also be produced by the addition of extra iron oxide before firing this combines with alumina which would otherwise form C3A, instead forming C4AF which is not affected by sulphates.

- It should be used in places with temperature is below 40°C.

- Compressive strength should be as follows:

3 Day ± 1 hr = 15 N/mm2

7 Day ± 2 hr = 22 N/mm2

28 Day ± 4 hr = 30 N/mm2 - It has low heat of hydration.

- It is used for construction of dams and other mass concreting works.

- Concrete made from super sulphated cement may expand if cured in water and may shrink if the concrete is cured in air.

- It has high resistance to chemical attack.

Normal Consistency Test

- The normal (standard) consistency of a cement paste is defined as that consistency which will permit a Vicat plunger having 10 mm diameter and 50 mm length to penetrate a depth of 33 to 35 mm from the top (or 5 to 7 mm from the bottom) of the mould.

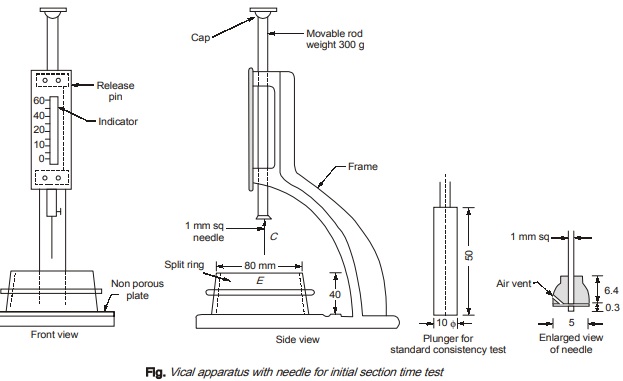

Vicat Apparatus:

- Vicat apparatus assembly consists of a plunger 300 gm in weight with a length of 50 mm and diameter of 10 mm and a mould which is 40 mm deep and 80 mm in diameter.

- There are two attachments for the plunger viz.:

(i) A square needle with 1 mm2 cross-section is attached to the plunger for initial setting time test.

(ii) A needle with an annular collar of 5 mm diameter is used for final setting time.

Test Procedure:

- To prepare the paste, take weighed quantity (300 g) of cement and place it in a crucible.

- Mix a weighed quantity of water (approximately 24% by weight of cement) for the first trial.

- The time of mixing or gauging should not be less than 3 minutes nor more than 5 minutes and gauging time should be counted from the time of adding water to the dry cement until commencing to fill the mould.

- The Vicat mould is filled with the paste, which is levelled off at its top.

- The mould is placed under the Vicat plunger.

- The vicat plunger is brought down to touch the surface of paste in the mould and quickly released allowing it to sink into the paste by its own weight.

- Take the reading by noting the depth of penetration of the plunger.

- Similarly conduct the trials with increasingly water/cement ratios till the time, the plunger penetrates for a depth of 33 to 35 mm from the top (or 5 to 7 mm from the bottom).

- That particular percentage of water which allows the plunger to penetrate to a depth of 33 to 35 from the top (or 5 to 7 mm from the bottom) is known as the percentage of water required to produce a cement paste of normal (standard) consistency. This percentage is generally denoted by P.

- This test should be conducted at a constant temperature of 27° ± 2°C and a constant humidity of 90%.

<< Previous | Next >>

Must Read: What is Construction Material?

Dear Aspirants,

Your preparation for GATE, ESE, PSUs, and AE/JE is now smarter than ever — thanks to the MADE EASY YouTube channel.

This is not just a channel, but a complete strategy for success, where you get toppers strategies, PYQ–GTQ discussions, current affairs updates, and important job-related information, all delivered by the country’s best teachers and industry experts.

If you also want to stay one step ahead in the race to success, subscribe to MADE EASY on YouTube and stay connected with us on social media.

MADE EASY — where preparation happens with confidence.

MADE EASY is a well-organized institute, complete in all aspects, and provides quality guidance for both written and personality tests. MADE EASY has produced top-ranked students in ESE, GATE, and various public sector exams. The publishing team regularly writes exam-related blogs based on conversations with the faculty, helping students prepare effectively for their exams.