Requirements of an Ideal Permanent Way

Following are the basic requirements of an ideal permanent way:

- The gauge should be uniform and correct.

- Both the rails should be at the same level in a straight track.

- On curves, proper superelevation should be provided to the outer rail.

- Track should have enough lateral strength.

- Track must have certain amount of elasticity.

- Radii and superelevation, provided on curves, should be properly designed.

- All joints, points and crossings should be properly designed.

- Drainage system should be perfect.

- It shoulde adequate provision of easy renewals and repairs.

- The components of track i.e., rail, fittings, sleepers, ballast must fully satisfy requirement for which they are provided.

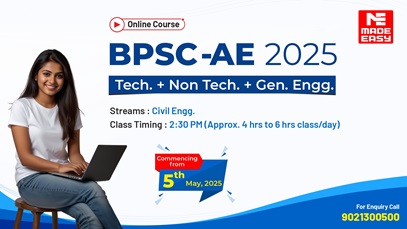

Coning of Wheels

- The tread or rim of railway vehicles are not made flat but are sloped and this sloping surface along the circumference forms part of a cone (with a slope of about 1 in 20). This is known as coning of wheels.

- On straight and level track, the wheel remains central and circumference of treads of both wheels are equal.

- On the level track as the axle moves towards one rail, the diameter of wheel tread over the rail increase while it decreases over the other rail. This prevents the further movement of axle and it retreat back to original position with equal diameters and equal pressure on both rails.

- On curved track, outer wheel has to travel greater length than the inner wheel. Vehicle on a curve has the tendency to move sideways towards the outer rail, so the circumference of the tread on the outer rail towards inner edge of the wheel becomes greater than that on the inner rail. This helps outer rail to cover a greater distance than the inner rail.

- Conicity of wheel is the angle between wheel tread and horizontal axis of axle.

Types of Rail Sections

The types of rail section which have been tried so far for constructing railway tracks are as follows:

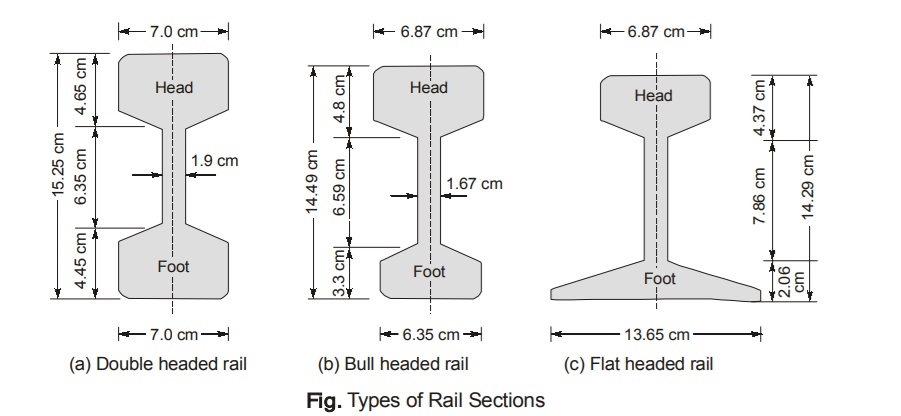

(i) Double headed rails (D. H. Rails)

- These rails indicate the early stage of development.

- It mainly consists of three parts (a) Upper table (b) Web (c) Lower table

- Both upper tables and lower tables were identical

- When upper table gets worn out, then the rails can be inverted and reused.

- This type of rail is practically out of use in Indian Railways.

(ii) Bull headed rails (B. H. Rails)

- The next evolution was that of bull– headed rails.

- It mainly consists of three parts (a) Head (b) Web (c) Foot

- Head has larger size than foot. So that even after wear, it can withstand stresses.

- Foot is designed only to furnish necessary strength and stiffness to rails.

- Bull headed rails are especially used for making points and crossing.

(iii) Flat footed rail (F. F. Rails)

- These rails are also called Vignole’s rails after the name of inventor.

- It consists of three parts (a) Head (b) Web (c) Foot

- The foot is spread out to form a base (as the name “Flat Footed” suggests)

- About 90% of the railway tracks in the world are laid with this form of rails.

- In India, flat footed rails are most commonly used.

Advantages of Flat Footed Rails:

- No requirement of chairs or keys (as the foot of the rail is directly spiked to the sleepers)

- This form of rail is stiffer both vertically and laterally then the full headed rail of equal weight.

- Less liable to develop kinks (maintain a more regular top surface than the full headed rails)

- More cheaper than the B.H. Rails

- Distributes the train load over a large number of sleepers (this results in greater track stability)

Disadvantage of Flat Footed Rails:

- Due to impact of rolling wheel loads, fitting get loosened more frequently.

<< Previous | Next >>

Must Read: What is Railway Engineering?

WhatsApp Group

Join Now

Telegram Group

Join Now