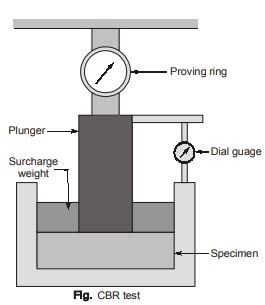

California Bearing (CBR) Test

This is a penetration test developed by the California Division of Highways to evaluate the stability of soil subgrade and other flexible pavement. It consists a standard piston have a diameter of 50 mm which is used to penetrate into the soil at the standard rate of 1.25 mm/min. the test may be performed in the laboratory on a prepared specimen in a mould or in-situ in the field. The test results can be used for correlating with the thickness requirement of pavement for highway and air fields.

Test Procedure

- Laboratory CBR apparatus consists a mould of 150 mm diameter with a base plate and a collar, a loading frame and dial gauges to measure the penetration.

- The specimen of soil is soaked in water for 96 hours and the swelling and water absorption values are noted.

- Load is applied on the sample by a standard plunger of diameter 50 mm at the rate of 1.25 mm/min.

- A graph is plotted between the load or pressure and penetration values .

- Load values are noted corresponding to the 2.5 mm and 5.0 mm penetration.

- Calculate the CBR value corresponding to 2.5 mm and 5.0 mm.

CBR (%) = Load carried by specimen at 2.5 or 5.0 mm penetration / Load carried by standard aggregates at corresponding penetration level x 100

Standard load values for 2.5 and 5.0 mm penetration over standard aggregated are given in Table below.

|

Standard load values |

||

|---|---|---|

|

Penetration (mm) |

Load (kg) |

Pressure2 (kg/cm ) |

|

2.5 5.0 |

1370

2055 |

70 105 |

Average CBR value of three test specimen is reported as the CBR value of the sample.

|

Typical CBR values of soils and their rating |

||

|---|---|---|

|

Soil |

Range of CBR values |

Rating |

|

Clay Silt Sand Gravel |

2 – 5

5 – 8 8 – 20 20 – 30 |

Very poor subgrade Poor subgrade Fair to good subgrade Excellent subgrade |

Cutback bitumen

Cutback bitumen is defined as the bitumen, viscosity of which has been reduced by a volatile diluent. A fluid binder which can be mixed at relatively low temperature is necessary for the use in surface dressings, some type of bitumen macadam and soil bitumen stabilization. Therefore, binder is blended with a volatile solvent to increase its fluidity at lower temperature. The volatile solvent gets evaporated after the work is completed and cutback develop the binding properties. It is to be noted that viscosity of cutback and rate at which it hardens on road depend on the characteristics and quality of both bitumen and volatile oil used as diluent.

On the basis of rate of curing or hardening after the application, bitumen can be classified into 3 types:

(i) Rapid curing (RC)

(ii) Medium curing (MC)

(iii) Slow curing (SC)

The grade of cutback or its fluidity is designed by a figure following the initials, for instance RC-2 means that it is a rapid curing cutback of grade-2. Here-numeral 2 designate the viscosity of cutback. The cutback with lowest viscosity is designated as 0 such as RC-0, MC-0, SC-0. As the thickness or viscosity of cutback increases, suffix numeral also increase in the order 0, 1, 2, 3, 4 and 5. In other words, RC-2, MC-2, SC-2 all have same initial viscosity at a specified temperature i.e. the cubacks having same suffix numeral will have same viscosity irrespective of their type.

|

Type and grade of cutback |

Viscosity in seconds in tar viscometer | ||

|

4 mm orifice 25°C |

10 mm 25°C |

10 mm 40°C |

|

|

RC-0, MC-O & SC-0 |

25 to 75 |

||

|

RC-1, MC-1 & SC-1 |

50 to 100 | ||

|

RC-2, MC-2 & SC-2 |

10 to 20 | ||

| RC-3, MC-3 & SC-3 |

25 to 75 |

||

| RC-4, MC-4 & SC-4 |

14 to 45 |

||

| RC-5, MC-5 & SC-5 |

60 to 100 |

||

Examples of

(i) Rapid curing cutbacks are bit Rapid curing cutbacks with a petroleum distillate such as naptha or gasoline which will rapidly evaporate after use in construction, leaving the bitumen binder.

(ii) Medium curing cutbacks are bitumen fluxed to greater fluidity by blending with an intermediate boiling point solvent like kerosene or light diesel oil.

(iii) Slow curing cutbacks are obtained either by blending bitumen with high-boiling point gas oil, or by controlling rate of flow and temperature of crude during first cycle of refining.

Various test carried out on cut-back bitumen are

(a) Viscosity test

(b) Distillation test to find distillation fractions

(c) Penetration test, ductility test and solubility test

(d) Flash point test using Pensky Martens closed type apparatus

Bitumen emulsion

A bitumen emulsion is liquid product in which a substantial amount of bitumen is suspended in a finally divided condition in an aqueous medium and stabilized by means of one or more suitable materials. It is basically a two phase system consisting of two immiscible liquids i.e. the one being dispersed as fine globules in other. Firstly, bitumen is broken up into fine globules and these globules are kept in suspension in water. Emulsifiers such as soaps, surface active agents or colloidal powders are also used in small proportions to facilitate formation of dispersion and to keep globulues of dispersed binder in suspension. The emulsifier basically form a protective coating around the globule of binder resisting the coagulation of globules.

The bitumen content of emulsions range from 40 to 60 percent and remaining portion is water. After the emulsion is applied on road, it breaks down and binder starts binding the aggregates, though the full binding power develops slowly as and when the water evaporates. The main advantage of emulsion is that it can be used in wet weather even when it is raining. These are also used in soil stabilization.

<< Previous | Next >>

Must Read: What is Highway Engineering?