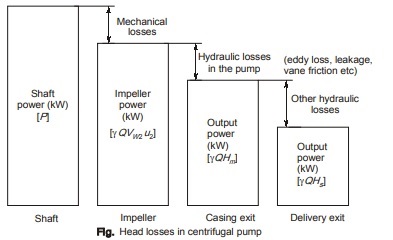

Efficiencies of Centrifugal Pump

The various losses that may occur in centrifugal pump are as follows:

(a) Hydraulic losses

– Friction loses in the impeller.

– Shock losses at the entry and exit of impeller.

– Friction and other minor losses in the suction pipe or delivery pipe.

– Eddy losses in guide vanes and casing.

(b) Mechanical losses

(c) Leakage losses

• Due to these losses different types of efficiencies are defined which are as follows:

(i) Manometric efficiency: It is defined as the ratio of manometric head developed by the pump to the head imparted by the impeller to the liquid.

Mathematically, manometric efficiency,

![]()

(ii) Volumetric efficiency: It is defined as the quantity of liquid discharged by the pump to the quantity passing per second through the impeller

![]()

(iii) Mechanical efficiency: It is defined as the ratio of power actually delivered by the impeller to the power supplied to the shaft by the motor.

![]()

(iv) Overall efficiency: It is defined as the ratio of power output from the pump to the power input from shaft.

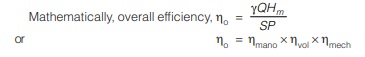

CAVITATION IN PUMPS

- If the absolute pressure at the suction side of pump drops below the vapour pressure of the liquid then cavitation occurs.

- Cavitation can be avoided if pressure at inlet is more and vapour pressure is less. Lower velocity at suction side reduces the friction loss in suction side, reduced temperature leading to reduction in vapour pressure etc. are helpful in eliminating cavitation.

Limitation on suction lift

Applying Bernoulli’s eq. between 1 and 2, we have,

PRIMING OF PUMP

- The process of filling the water or removing the air from casing and suction pipe is known as priming of pump.

- Priming is done to ensure that the impeller does work directly on water.

- Before starting a pump, its impeller and suction pipe have to be filled with water in order to remove any air, gas from the waterway of the pump.

- If a centrifugal pump is not primed before starting, air pockets inside the impeller may give rise to vortices and cause discontinuity of flow.

- As we know that head generated by the revolving impeller depends upon the density of fluid, so when air, whose density is 800 times less than water, is mixed with water the head generated gets reduce greatly

where, NPSH = (Ha– hs) – Hv

Ha = atmospheric pressure head

Hv = vapour pressure head

hs = suction head

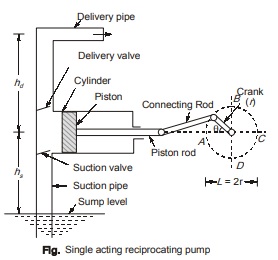

Working of Reciprocating pump

- It is used for relatively small discharge to be pumped to high head.

- Reciprocating pump operates at low speed but the rotating speed of the energy supplying equipment is high. Hence it is coupled to electric motor by V-belt so that rpm of pump can be reduced.

- Both the suction and delivery pipe valves are one way or non-return valves.

- As the crank is rotating from A to C, the piston is moving towards right in the cylinder. It will create a partial vacuum in the cylinder.

- Pressure at surface of liquid in sump is atmospheric which is more than the pressure inside the cylinder.

- Therefore liquid is forced in suction pipe from sump which opens the suction valve and enters the cylinder.

- When the crank rotates from C to A, the piston from its extreme right moves towards left in the cylinder. This movement increases the pressure inside the cylinder more than atmospheric pressure, due to which suction valve is closed and delivery valve to be opened. And hence liquid is forced into the delivery pipe and is raised to the required level.

Design Parameters of Reciprocating Pump

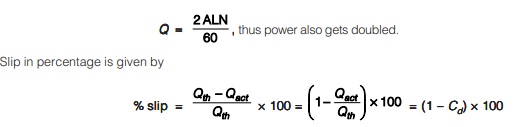

- Volume of water discharged per second,

Q = ALN/60 m3/s

where,

A = Area of cylinder (in m2)

L = Length of cylinder (in m)

N = Crank speed (in rpm)

- If the head against which water is to be lifted is

Hs = hs + hd

where, hs= suction head, hd = delivery head - Work done per second = γQ(hs + hd)

- Reciprocating pumps are used to lift water against high head at low discharge.

- To increase discharge and to maintain it more uniform, double acting reciprocating pumps are used.

where Cd= Coefficient of discharge

Slip is negative when

(i) delivery pipe is small and suction pipe is long

(ii) Pump is running at very high speed.

CENTRIFUGAL PUMP VS RECIPROCATING PUMP

|

Centrifugal Pump |

Reciprocating Pump |

| Discharge is continuous and smooth

Starting torque is more Maintenance cost is less Can run at highest speeds Less wear and tear Less efficiency Cost of centrifugal pump is less Needs smaller floor area Suction and delivery valve is not necessary |

Discharge is fluctuating and pulsating

Starting torque is less Maintenance cost is more Cannot run at higher speeds More wear and tear More efficiency Cost of reciprocating pump is approximately four times the cost of centrifugal pump Requires large floor area and maintenance cost is high Suction and delivery valve is necessary |

<< Previous | Next >>

Must Read: What is Fluid Mechanics?