Types of Screens

Depending upon the size of the openings, types of screens may be classified as following:

(a) Coarse Screens:

They are also known as Racks and the spacing between the bars (i.e opening size) is about 50 mm or more. These screens helps in removing large floating objects from sewage. They will collect about 6 litres of solids per million

litre of sewage. The materials separated by coarse screens, usually consists of rags, wood, paper etc, which will not putrefy and may be disposed of by incineration, burial or dumping.

(b) Medium Screens:

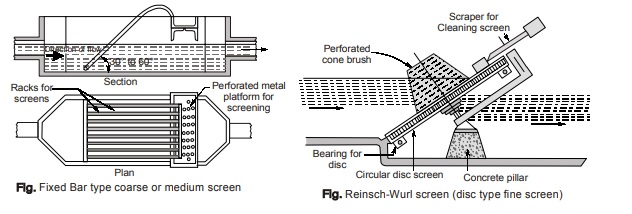

In these screens, the spacing between bars is about 6 to 40 mm. These screens will ordinarily collect 30 to 90 litres of material per million of sewage. The material separated by screenings usually contains some quantity of organic material, which may putrefy and become offensive, and must, therefore, be disposed of by incineration or burial (not by dumping). Rectangular shaped coarse and medium screens are now a days widely used at sewage treatment plants. They are made of steel bars, fixed parallel to one another at desired spacing on a rectangular steel frame and are called bar screen. The screens are set in a masonry or RCC chamber, called the screen chamber.

Now a days, these screens are generally kept inclined at about 30° to 60° to the direction of flow, so as to increase the opening area and to reduce the flow velocity and thus making the screen more effective. While designing the screens, clear openings should have sufficient total area, so that the velocity through them is not more than 0.8 to 1 m/sec. These limits, placed on velocity, limits the head loss through the screens and thus, reduces the opportunity for materials to be pushed through the screens. The material collected on bar screens can be removed either manually or mechanically. Manual cleaning is practised at small plants with hand operated rakes. Large plants, however, use mechanically operated rakes, which move over the screens, either continuously or intermittently.

Screen can also be classified as fixed or movable, depending upon whether the screens are stationary or capable of motion. Fixed screens are permanently set in position. Movable screens are stationary during their operating periods. But they can be lifted up bodily and removed from their positions for the purpose of cleaning. It is mainly used in deep pits ahead of pumps.

(c) Fine Screens:

They have perforation of 1.5 mm to 3 mm in size. The installation of these screen prove very effective, and they remove as much as 20% of the suspended solids from sewage. These screens, however get clogged very often and need frequent cleaning. They are, therefore, used only for treating the industrial waste water or for treating those municipal wastewater, which are associated with heavy amounts of industrial wastewater.

Brass or bronze plates or wire mesh are generally used for constructing fine screens. The metal used should be resistant to rust and corrosion. The fine screens may be disc or drum type, and are operated continuously by electric motors. Figure shows a typical disc-typefine screen, which is cleaned by a cone brush.

<< Previous | Next >>

Must Read: What is Environmental Engineering?

Dear Aspirants,

Your preparation for GATE, ESE, PSUs, and AE/JE is now smarter than ever — thanks to the MADE EASY YouTube channel.

This is not just a channel, but a complete strategy for success, where you get toppers strategies, PYQ–GTQ discussions, current affairs updates, and important job-related information, all delivered by the country’s best teachers and industry experts.

If you also want to stay one step ahead in the race to success, subscribe to MADE EASY on YouTube and stay connected with us on social media.

MADE EASY — where preparation happens with confidence.

MADE EASY is a well-organized institute, complete in all aspects, and provides quality guidance for both written and personality tests. MADE EASY has produced top-ranked students in ESE, GATE, and various public sector exams. The publishing team regularly writes exam-related blogs based on conversations with the faculty, helping students prepare effectively for their exams.