Mechanism of Coagulation

The mechanism of destabilization (Removal of “little or no tendency of colloids to aggregate”) of colloids are classified in four types:

Mechanism of destabilization

(a) Ionic layer compression

(b) Adsorption and charge neutralization

(c) Sweep coagulation

(d) Interparticle bridging

a) Ionic Layer Compression

Total quantity of ions in water surrounding a colloid has an effect on reducing the repulsive force. A high ion concentration compresses the layer composed predominantly of (+ve) charge ions towards the surface of colloid. But if this layer is sufficiently compressed, then attractive forces (Vander Waal force) will be predominant. Thus, the particles will grow in size and hence, they will be removed in sedimentation tank.

(b) Adsorption and Charge Neutralization

These cations surrounds the clouds of (–ve) charge and as they have an affinity for surface, they are adsorbed on to the surface. Finally, when the charge is neutralized, free contact can occur. Thus, size of particles increases and settling takes place under gravity. This shows that electrostatic forces are not the only driving forces for destabilisation but also adsorption plays an important role. Otherwise, restabilisation would have been produced.

(c) Sweep Coagulation

Precipitate of Al(OH)3 (Aluminium hydroxide) formed when alum is added to water, which is an amporphous (shapeless) and gelatinous (sticky) precipitate (flocs). These are heavier than water and settle down by gravity. Colloids may become entrapped in the flocs as the flocs settle down. The process by which colloids are swept away from the system in this manner is called sweep coagulation.

(d) Inter-Particle Bridging

Large molecules may be formed when aluminum or ferric sulphate dissociate in water like Al7(OH) 4+ 17.

Several colloids may become attached to single molecule or various molecules may get enmeshed resulting in

settleable mass. Polymer may also be used either alone or in combination with alum or iron salts as a coagulant

Some important points regarding coagulation:

The study of relationship among pH, colloidal concentration of water and optimum coagulant dose is necessary for satisfactory operation of a coagulation process.

(a) High turbidity – Low alkalinity of water

(b) High turbidity – High alkalinity of water

(c) Low turbidity – High alkalinity of water

(d) Low turbidity – Low alkalinity of water

(a) High Turbidity-Low Alkalinity of Water:

This type of water is coagulated with low doses of coagulants. The optimum coagulant dosage has to be estimated for destabilization of colloids. Reduction of pH (4 to 6) can occur by ionization of coagulants, which gives hydroxometal polymers (Al(OH)3) or aquametallic ions [Al(OH)+2 + Al(OH)2+]. These metal ions adsorb on the colloids because they have great affinity for surfaces where they neutralize the surface charge.

(b) High Turbidity-High Alkalinity of Water:

This type of water is unaffected by the addition of coagulants. The reduction of pH is less and remain in the neutral region. Hence, adsorption and charge neutralization will be less effective than in low turbidity water. Higher coagulant dosage should be used to ensure sweep coagulation.

(c) Low Turbidity-High Alkalinity of Water:

Due to low colloidal concentration, the low dose coagulation is less effective. Hence, high coagulant dosages will enmesh the colloidal particles and form “Sweep floc”. Addition of coagulant aid (e.g. Bentonites clay) will help to reduce the high coagulant dosage.

(d) Low Turbidity-Low Alkalinity of Water:

Low colloidal concentration reduces the effectiveness of low dose coagulation and low alkalinity permits the effective formulation of Al(OH)3 floc. It may be useful to add both turbidity and alkalinity.

Commonly Used Coagulants

The most commonly used water treatment coagulant is based primarily on Aluminium and Iron salts. Natural polyelectrolytes have been used for many years in several developing countries for clarifying water. For instance John (1979) reports that in several African countries (Chad, Nigeria, Sudan) indigenous plants are added to drinking water by rural villages to remove turbidity, taste and odour.

The common coagulants added in water:

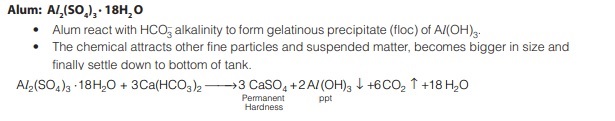

(a) Alum

(b) Copperas

(c) Chlorinated copperas

(d) Sodium aluminate

(e) Lime

Lime is used as a secondary coagulant in drinking water treatment but as a primary coagulant in waste water treatment

So, this reaction introduces permanent hardness in water in the form of calcium sulphate. and the carbon dioxide gas, which is evolved, causes corrosiveness.

So, this reaction introduces permanent hardness in water in the form of calcium sulphate. and the carbon dioxide gas, which is evolved, causes corrosiveness.

- The turbidity and colour of raw water determines the dose of coagulant (alum) and this amount is estimated with the help of Jar test.

- Normal alum dose is 10-30 mg/litre of water and is very effective in the pH range of 6.5 to 8.5.

- Alum coagulant is cheap and the flocs formed are very stable.

- Alum also reduces colour, taste and odour but only disadvantage is that it is difficult to dewater the sludge formed.

Comparison of Aluminum and Iron Salts as Coagulant

The alum and the iron salts are having their own advantages and disadvantages as summarized below:

- Iron salts produce heavy floc and can, therefore, remove much more suspended matter than the alum.

- Iron salts form precipitate rapidly in comparision to aluminium salts.

- Iron salts, being good oxidising agents, can remove hydrogen sulphide and its corresponding tastes and odours from water.

- Iron salts can be used over a wider range of pH values.

- Iron salts cause staining and promote the growth of iron bacteria in the distribution system.

- Iron salts impart more corrosiveness to water than that which is imparted by alum.

- The handling and storing of iron salts require more skill and control, as they are corrosive and deliquescent. Whereas, no such skilled supervision is required for handling alum.

<< Previous | Next >>

Must Read: What is Environmental Engineering?