Grit Removal Basins

Grit removal basins, such as Grit chamber or Grit channels or Detritus tank are the sedimentation basins placed in front of the wastewater treatment plant to remove the inorganic particles such as sand, gravel, grit, shells, bones and other non-putresible materials that may clog channels or damage pumps due to abrasion and to prevent their accumulation in sludge digesters.

Grit chambers are infect, nothing but like sedimentation tanks designed to separate the intended heavier inorganic materials by the process of sedimentation due to gravitational forces and to pass forward the lighter organic materials.

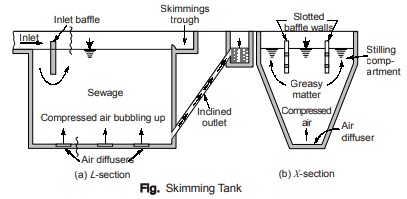

Skimming Tanks

Skimming tanks are employed for removing oils and grease from the sewage. They are placed before the sedimentation tanks. They are used where sewage contains too much of grease or oils, which include fats, waxes, soaps, fatty acids, etc. These materials may enter into the sewage from the kitchens of restaurants and houses, from motor garages, oil refineries, soap and candle factories, etc. They are, thus, normally present in large amounts in the industrial wastewaters.

If such greasy and oily matter is not removed from the sewage before it enters further treatment units, it may form unsightly and odourous scums on the surface of the settling tanks, or interfere with the activated sludge treatment process and inhibit biological growth on the trickling filters.

These oil and greasy materials may be removed in a skimming tank, in which air is blown by an aerating device through the bottom. The rising air tends to coagulate and congeal (solidify) the grease and cause it to rise to the surface (being pushed in separate compartments), from where it is removed.

These tanks consists of a long trough shaped structure divided into two or three lateral compartments by means of vertical baffle walls. The baffle walls help in pushing the rising coagulated greasy material into the side compartments. The rise of oils and grease is brought about by blowing compressed air into the sewage from diffusers placed at the bottom of the tank. Sewage enters the tank from one end, flows through longitudinally, and finally goes out through a narrow inclined duct as shown. This is so narrow that the suspended heavier particles are carried up its slope and out of the tank. A detention period of about 3 to 5 minutes is usually sufficient, and the amount of compressed air required is about 300 to 6000 m3 per million litres of sewage. The surface area required for the tank can be found out by using the formula.

A = 0 00622 / Vr

where,

q = rate of flow of sewage in m3/day

Vr = minimum rising velocity of greasy material to be removed in m/minute

= 0.25 m/minute in most of the cases.

The efficiency of a skimming tank can be increased considerably by passing chlorine gas (2 mg per litre of sewage) along with the compressed air.

The action of chlorine is to destroy the protective colloidal effect of protein, which holds the grease in emulsified form. It may sometimes be digested in digesters, which prove beneficial only if the mineral oils are less in amount and vegetable and organic matters predominate. The latter digest easily, and produce gases of high fuel value. In hot countries like India, it is very difficult to skim out the oils and grease, because they do not coagulate and congeal (solidify due to cooling) easily. Attempts are, therefore, generally made in India, to remove the greasy matters before they enter the municipal sewers, by constructing oil and grease traps. Skimming tanks are, however to be provided in particular industrial town’s, or at colder hill stations like Shimla, Mussoorie, Nainital, etc., where the greasy materials may congeal easily.

<< Previous | Next >>

Must Read: What is Environmental Engineering?

Dear Aspirants,

Your preparation for GATE, ESE, PSUs, and AE/JE is now smarter than ever — thanks to the MADE EASY YouTube channel.

This is not just a channel, but a complete strategy for success, where you get toppers strategies, PYQ–GTQ discussions, current affairs updates, and important job-related information, all delivered by the country’s best teachers and industry experts.

If you also want to stay one step ahead in the race to success, subscribe to MADE EASY on YouTube and stay connected with us on social media.

MADE EASY — where preparation happens with confidence.

MADE EASY is a well-organized institute, complete in all aspects, and provides quality guidance for both written and personality tests. MADE EASY has produced top-ranked students in ESE, GATE, and various public sector exams. The publishing team regularly writes exam-related blogs based on conversations with the faculty, helping students prepare effectively for their exams.