Analysis of Pipe Network

Analysis of pipe network includes determination of quantities of flow and head loss in various pipelines and the resulting residual water head.

The Hazen-Williams formula is mostly used for computation of flow through pipes, and following two methods are used for analysis.

Methods are used for Analysis

(i) Equivalent pipe method

(ii) Hardy cross method

Equivalent Pipe Method

- In equivalent pipe method, different small loops are replaced by an imaginary single equivalent pipes having same discharge capacity and causing same head loss.

- The equivalent pipe method is used in solving large networks of pipes.

Hardy Cross Method

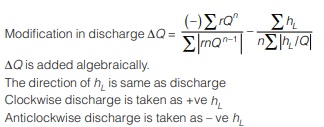

In Hardy Cross method of analysis, a distribution of flow in the network is assumed and resulting head losses are balanced. Formula of the pipe flow are used to evaluate losses and successive connections are made in the flow until the network is hydraulically balanced. In pipe network, following two conditions are to be satisfied:

(i) The algebraic sum of the pressure drops around a closed loop must be equal to zero. i.e. In each loop loss of head due to flow in clockwise direction must be equal to loss of head due to flow in anticlockwise direction.

(ii) The flow entering a junction must be equal to the flow leaving the same junction.

Here, loss of head is hL = rQn

Steps for computation of discharge through each pipe:

Assume flow in each pipe satisfying continuity equation.

Take clockwise flow as positive, anticlockwise flow as negative.

Water Meter

- Water meters are connected after the stopcock to measure the quantity of water supplied to a building.

- Water meters are classified according to the method of measuring flux. Mainly, there are two types of meters.

(i) Velocity or inferential meters

- Such types of meters measure the horizontal velocity of water flowing through them.

- They measure large flow and are often used by industries for measuring large supply.

- They have an additional advantage of measuring water containing suspended particles.

(ii) Positive or Displacement Meters

- They work by the flow of water causing a piston to reciprocate within a cylinder or communicating the movement finally to a system of dials, which register the quantity of flow.

- Such type of meters are very bulky and heavy, hence, an improvement has been done and the improved ones are known as semi-positive meters. semi-positive meters.

- They are widely used for domestic supplies.

The two most common type of semi-positive meters are

(a) Rotary piston meters

(b) Rotating disc meters

In selecting a type of meter for a particular use, the following points should be considered.

(a) Quantity of flow to be measured

(b) Nature of flow (whether continuous or intermittent)

(c) Permissible head loss (should not be more than 3 m)

(d) Cost (the inferential meters being less costly)

Metal Pipes

The following types of metal pipe are used

(i) Cast-iron pipes

(ii) Steel pipes

(iii) Wrought iron pipes

(iv) Copper, lead and brass pipes

(i) Cast Iron Pipes:

Cast iron pipes are most widely used in water supply for trunk as well as distributary mains due to their durability, strength, resistance to corrosion, ease in laying and simplicity in repairs and maintenance. There are two general processes for manufacture of cast iron water pipes :

- Foundry method

- The centrifugal process

(a) Foundry Method: Foundry method of casting is done in fire sand moulds or more popularly brown pit-cast pipe. Pipes are cast in vertical moulds with hub end down for pipes greater than 45 cm diameter and horizontally casted pipes are called Mc. Wane Pipes.

(b) The Centrifugal Process: The Centrifugal Process: this process, the core is omitted and the mould placed horizontally is rotated while the iron is pored so that by centrifugal force the molten iron is evenly distributed

around the mould. Pipes made by centrifugal process have less variation in thickness, are stronger and more uniform as well as lighter. They are popularly known as spuniran.

Disadvantages of cast iron pipes are:

- Water carrying capacity decrease with the time, as the valve friction factor increases due to tuberculation in certain waters.

- They cannot be used for high pressure. Generally, not used for pressure above 700 kN/m2

- When large, they are very heavy and uneconomical.

- They are likely to break during transportation or while making connection.

(ii) Steel Pipes: Steel Pipes of larger sizes made from steel plate made to circular form

- Used as water mains passing over bridges and culverts of longer span.

- Steel pipes are frequently used for raw water trunk mains, inverted syphons, or pumping mains, where pressure is high and sizes are larger.

- Life is generally taken around 40 years under ordinary conditions.

- Steel pipes are not adapted to withstand external loads of backfill, traffic etc. while a partial vacuum caused by emptying of the pipe may cause collapse or distortions if not designed properly.

<< Previous | Next >>

Must Read: What is Environmental Engineering?

Dear Aspirants,

Your preparation for GATE, ESE, PSUs, and AE/JE is now smarter than ever — thanks to the MADE EASY YouTube channel.

This is not just a channel, but a complete strategy for success, where you get toppers strategies, PYQ–GTQ discussions, current affairs updates, and important job-related information, all delivered by the country’s best teachers and industry experts.

If you also want to stay one step ahead in the race to success, subscribe to MADE EASY on YouTube and stay connected with us on social media.

MADE EASY — where preparation happens with confidence.

MADE EASY is a well-organized institute, complete in all aspects, and provides quality guidance for both written and personality tests. MADE EASY has produced top-ranked students in ESE, GATE, and various public sector exams. The publishing team regularly writes exam-related blogs based on conversations with the faculty, helping students prepare effectively for their exams.