Mechanism of Load Transfer Thought Bolts

- The transfer of force from one member to another depends on the type of bolt being used.

- This transfer of force mechanism may be either bearing type where load transfer occurs by shearing and bearing or slip-critical/slip-resistant where load transfer occurs by friction.

- In slip resistant connections, the entire force is transmitted through friction and the joints are not really subjected to shear or bearing. The bolts are first brought to sung tight condition and then tightened further. Joints with so tightened bolts are referred to as pre-tensioned joints. But when the load exceeds the frictional resistance then slippage occurs and consequently the bolts will be subjected to shear and bearing and will behave like a bearing type joint.

- When high strength bolts are not tightened sufficiently so as to significantly squeeze the plates together, there will be a negligible friction between the plates. On load application, the plates slip a little and the load will tend to shear off the bolts on the interface and press or bear against the side of the bolts. Now the load transfer will be like bearing type connection.

Shear Strength of Bolts

- The shank of the bolt shears along the plane of slip i.e. at interface.

- The number of planes along which a bolt can get sheared indicates the number of shear i.e. single shear or the double shear.

- The resistance of bolt in shear is referred to as shear capacity of bolt denoted as Vnsb. It depends on the ultimate tensile strength of the bolt fub, the number of shear planes n, the nominal area of shank Asb and the net tensile stress area Anb of bolt in each shear plane.

- The nominal shear capacity of a bolt is given by,

![]()

- The nominal shear capacity of bolts for long joints, long grip length and with packing plates (if provided) will be less and is modified as

![]()

fub = Ultimate tensile strength of the bolt

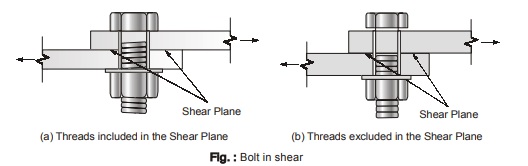

nn = Number of shear planes with threads intercepting the shear plane

ns = Number of shear planes without threads intercepting the shear plane

βlj = Reduction factor to allow for the overloading of the end bolts occurring in long connections

βlg = Reduction factor to allow for the effect of large grip length

βpkg = Reduction factor to account for packing plates in excess of 6 mm

- For bolt to be safe in shear, the strength of bolt Vnsb i.e. the maximum factored shear force the bolt

can carry should be greater than the design shear strength of the bolt Vdsb i.e.,

Vnsb ≥ Vdsb - The design shear strength of bolt is given by

Vdsb = Vnsb/γmb

where γmb = Partial factor of safety for the bolt material = 1.25

Thus design shear strength of the bolt can be expressed as,

![]()

Bearing Strength of Bolt

- Tests on bolted joints reveal that the nominal bearing strength of bolts do not depend upon the grade of bolt and the metal in contact with them. However, it is observed that the magnitude of bearing stresses do affect the efficiency of connected parts. Thus IS code limits the value of nominal bearing strength so that the strength of connected parts is not impaired. These bearing stresses therefore, are indexes of efficiencies of connected parts only and are not specified to protect bolts against bearing failure.

- From the above discussion it is evident that the bearing strength of bolted connection is a function of strength of connected parts and bolts arrangement only.

- A possible failure mode resulting from excessive bearing is the shear tear out at the end of connected element as shown in figure, which can take place either at the end of a connected part or between two holes in the direction of bearing.

- The determination of bearing strength of bolt thus involves the bearing deformation perceived, bolt hole type, pitch (p), end distance (e) and the specified minimum tensile strength (fu) of the connected parts.

<< Previous | Next >>

Must Read: What is Power Electronics?

Dear Aspirants,

Your preparation for GATE, ESE, PSUs, and AE/JE is now smarter than ever — thanks to the MADE EASY YouTube channel.

This is not just a channel, but a complete strategy for success, where you get toppers strategies, PYQ–GTQ discussions, current affairs updates, and important job-related information, all delivered by the country’s best teachers and industry experts.

If you also want to stay one step ahead in the race to success, subscribe to MADE EASY on YouTube and stay connected with us on social media.

MADE EASY — where preparation happens with confidence.

MADE EASY is a well-organized institute, complete in all aspects, and provides quality guidance for both written and personality tests. MADE EASY has produced top-ranked students in ESE, GATE, and various public sector exams. The publishing team regularly writes exam-related blogs based on conversations with the faculty, helping students prepare effectively for their exams.