Bolted Connections over Riveted Connections

Advantages and Disadvantages of Bolted Connections over Riveted Connections

Advantages:

(a) Bolted connections facilitate faster erection of structure.

(b) Not too much skilled labours are required for making the bolted connections.

(c) Bolted connection is more economical than riveted connection because cost of skilled labour is reduced as well as equipment costs are also very less.

Disadvantages:

(a) The cost of material is high almost twice that of rivets.

(b) Because of reduced area at the root of the thread, the tensile strength of the bolt is reduced and also stress concentration occurs.

(c) Bolts are usually of low fit (except the turned bolts) and thus they have reduced strength.

(d) In case of dynamic loads where vibrations occur and also in case of shock loadings, bolts get loosened up.

Types of Bolted Joints

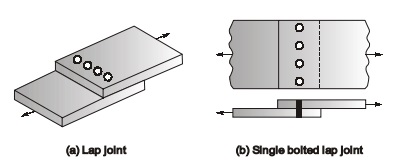

If the load line is assumed to pass through the CG of the bolt group then there are two types of bolted joints viz. lap joint lap joint and butt joint. butt joint. The other case i.e. when the load line does not pass through the CG of the bolt group gives rise to eccentric connections.

(a) Lap joint

- Here the two members to be connected are overlapped and jointed as shown below in figure (a) lap joints.

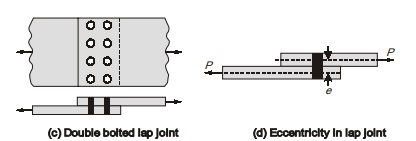

- Figure (b) and (c) shows respectively the single bolted lap joint and the double bolted lap joint. The load lines in the two members of lap joint do not coincide and hence lap joint has an eccentricity leading to the formation of an undesirable couple there by inducing tension in bolt which may lead to failure of joint as shown in figure (d).

- Due to this eccentricity only, the stresses are distributed unevenly across the contact area between the bolts and members to be connected.

- Cl. 10.5.1.2 of IS 800:2007 states that minimum length of lap shall not be less than four times the thickness of thinner part being jointed or 40 mm, whichever is more.

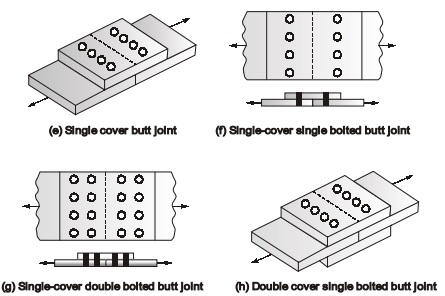

(b) Butt joint

- Here the two members to be connected are placed end to end thereby bringing the load lines in the two members in one line and reducing eccentricity to almost zero.

- Additional cover plate(s) on either side or both sides can be provided to connect the main plates as shown in figure (e) and (h).

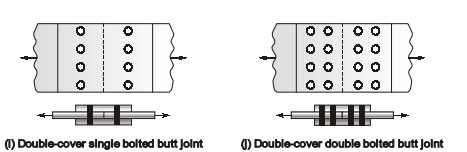

- The butt joint is called as single cover butt joint single cover butt joint if single cover butt joint the plate is provided only on one side of the main plate as shown in figure (e), (f) and (g) and is called as double cover butt joint double cover butt joint if double cover butt joint the plates are provided on both the sides of the main plate as shown in figure (h), (i) and (j).

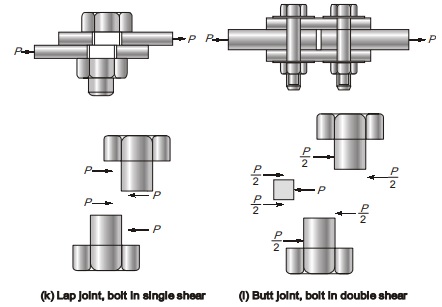

- Figure (k) and (l) shows the transfer of forces in lap joint and double cover butt joint respectively.

Advantages of butt joint over lap-joint:

(a) As shown in figure (l), the total shear that gets transferred through double cover butt joint is almost half of that of lap joint as shown in figure (k).

(b) In case of double cover butt joint, there does not exist the eccentricity of load line and hence bending is eliminated. But this bending exists in lap joint