Soundness Test

- Soundness test of cement indicates that the cement paste, once it has set, does not undergo appreciable change in volume causing concrete to crack.

- The cement having some quantity of free lime, magnesia and excess sulphates undergoes large changes in volume as the time elapses tending to cause cracks.

- The soundness of cement is determined either by ‘Le Chatelier’s method’ or by means of ‘Autoclave’ test.

- No satisfactory test is available for assessment of soundness due to excess of calcium sulphate, but its content can be easily determined by chemical analysis.

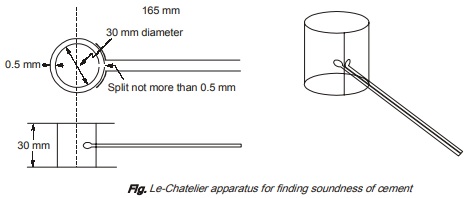

(a) Le Chatelier Method:

- The Le Chatelier’s apparatus consists of a small split cylinder of spring brass. It is 30 mm in diameter and 30 mm high. On either side of the split, two indicator arms of 165 mm long with pointed ends are attached.

- Take 100 gm of cement and make a cement paste of consistency 0.78 P.

- Fill the cement paste in the mould and keep it on a glass plate.

- Cover the mould on the top by another glass plate.

- The whole assembly is immersed in water at a temperature of 27°-32°C and kept there for 24 hours.

- The assembly is taken out after 24 hours and the distance between the indicator points is measured.

- The mould is then immersed in a water bath.

- The water of the bath is brought to boiling point with the mould submerged in 25 to 30 minutes and kept boiling for 3 hour.

- The mould is taken out from water and allowed to cool.

- Distance between the indicator points is then measured.

- The difference between the two measurements represents the expansion of cement.

- The Le Chatelier’s method detects unsoundness due to free lime only.

- This method of testing does not indicate the presence and after effect of the excess of magnesia and calcium sulphate.

- The expansion of cement must not exceed 10 mm for OPC, rapid hardening and low heat Portland cements by this method. Whereas, high alumina cement and super sulphated cement can have maximum expansion less than 5 mm.

(b) Autoclave Test:

- Indian Standard specification recommends that a cement having a magnesia content of more than 3 percent shall be tested for soundness by autoclave test which is sensitive to both free magnesia and free lime.

- In this test, a cement paste of 25 mm × 25 mm × 250 mm is placed in a standard autoclave.

- Now, the steam pressure inside the autoclave is raised at such a rate so as to bring the gauge pressure of the steam to 21 kg/cm2 in 1 hour to 1 hour 15 minutes from the time the heat is turned on.

- This constant pressure is maintained for three hours.

- The autoclave is cooled and length of the specimen is measured again.

- The expansion should not exceed.

– 0.8% for OPC (33, 43, 53); SRC; PPC, RHC, LHC, Slag cement.

– 1% for masonry cement.

Strength Test

(a) Compressive Strength Test:

- The compressive strength of the hardened cement is the most important of all the properties.

- Take 600 gm of standard sand (Ennore sand), 200 gm of cement (i.e. ratio of cement to sand is 1: 3) and mix them with a trowel for one minute.

- Add water of quantity (P/4 + 3.0) % of combined weight of cement and sand where P is the percentage of water required to produce a cement paste of normal consistency.

- This time of mixing should not be less than 3 minutes and not more than 4 minutes.

- Immediately, after mixing, the mortar is filled in a cube mould of size 7.06 cm. The area of the face of cube should be 50 cm2.

- Compact the mortar either by hand compaction in a standard specified manner or on the vibrating equipment for 2 minutes. (vibrations = 1200 ± 400 vibrations/minute)

- Keep the compacted cube mould at a temperature of 27° ± 2°C and at least 90% relative humidity for 24 hours.

- After 24 hours, the cubes are removed from the mould and immertsed in clean fresh water until taken out for testing.

- Three cubes are tested for compressive strength at 1 day, 3 days, 7 days and 28 days each where the period of testing being reckoned from the completion of vibration.

- Load applied gradually as 0 to 35 N/mm2/min on cubes by using compressive testing machine (UTM machine).

- The compressive strength shall be the average of the strengths of the three cubes for each period respectively.

- The compressive strength of 33 grade OPC at 3 days, 7 days and 28 days is 16 MPa, 22 MPa and 33 MPa respectively.

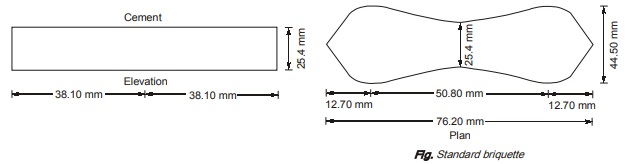

(b) Tensile Strength Test:

- The tensile strength of cement may be obtained by Briquette test.

- A mixture of cement and sand is gauged in the proportion of 1:3 by weight.

- The percentage of water to be used is calculated by the formula ( P/5 + 2.5 ) % where P is percentage of water required to produce a paste of standard consistency.

- The mix is filled in the briquette moulds and the surface of the mould is finished with the blade of a trowel.

- Briquette mould is then kept for 24 hours at a temperature of 27° ± 2°C and in an atmosphere having 90% humidity.

- The briquettes (6.45 cm2) are then kept in clean water and are taken out before testing.

- Six briquettes are tested and average tensile strength is calculated.

- Load is applied steadily and uniformly, starting from zero and increasing at the rate of 0.7 N/mm2 in 12 seconds.

- OPC should have a tensile strength of not less than 2 MPa and 2.5 MPa after 3 and 7 days respectively.

- Generally tensile strength is 10-15% of compressive strength.

<< Previous | Next >>

Must Read: What is Construction Material?

Dear Aspirants,

Your preparation for GATE, ESE, PSUs, and AE/JE is now smarter than ever — thanks to the MADE EASY YouTube channel.

This is not just a channel, but a complete strategy for success, where you get toppers strategies, PYQ–GTQ discussions, current affairs updates, and important job-related information, all delivered by the country’s best teachers and industry experts.

If you also want to stay one step ahead in the race to success, subscribe to MADE EASY on YouTube and stay connected with us on social media.

MADE EASY — where preparation happens with confidence.

MADE EASY is a well-organized institute, complete in all aspects, and provides quality guidance for both written and personality tests. MADE EASY has produced top-ranked students in ESE, GATE, and various public sector exams. The publishing team regularly writes exam-related blogs based on conversations with the faculty, helping students prepare effectively for their exams.