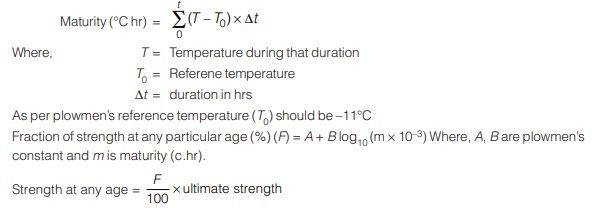

Maturity of Concrete

- It is a parameter which incidates the fraction of strength gain at any particular age.

- The strength of concrete depends on both period of curing (i.e. age) and temperature during curing.

- The product (period × temperature) is called the maturity of concrete.

- It is measured in °C hours to °C days.

DEFECTS IN CONCRETE

The different types of defects occuring in concrete are as follows:

(a) Cracks

- Cracks are inherent in concrete and cannot be completely prevented but can be minimized.

The reasons for cracks in a concrete are:

(a) Excess water

(b) Early loss of water

(c) Alkali aggregate reaction

(d) Freezing and thawing

(b) Efflorescence

- It is appearance of fluffy white patches on the surface of concrete members.

- It is caused by poorly washed aggregate, salty water used in making concrete. The salts being leaching out to the surface by rain water afterwards on evaporation white patches appear on the surface.

(c) Segregation

- It is separation of (a) coarse aggregate from fine aggregate, (b) cement paste from coarse aggregate, or water from the mix and the ingredients of the fresh concrete no longer remain uniformly distributed.

- It can be reduced by increasing small size aggregate, by using air entrainment, using dispersing agents and pozzolona.

- Causes of segregation are:

(i) Excess water.

(ii) Dropping concrete from heights.

(iii) Badly design mixes.

(iv) Concrete carried over long distances by pumping, belt-conveyor system etc.

(v) Over vibrations.

(vi) Extra floating and tamping during concrete finishing.

(d) Bleeding

- It is a flow of mixing water within or emergence to the surface from freshly placed concrete usually due to excessive vibrations imparted to concrete to achieve full compaction.

- Bleeding can be reduced by the use of uniformly graded aggregates, pozzolona – by breaking the continuous water channel or by using air-entraining agents, finer cement and a rich mix.

WATER-CEMENT RATIO AND ABRAHM’S LAW

- The water in concrete performs the following two functions:

(i) It enters into chemical action with cement and causes the setting and hardening of concrete.

(ii) It lubricates the aggregates and facilitates the passage of cement through the voids of aggregates thus making the concrete workable. - The water-cement ratio is one of the major factor influencing the strength of concrete. It is mainly responsible for the porosity of hardened cement paste.

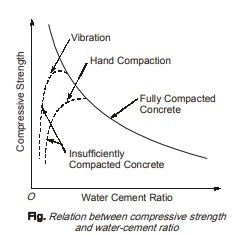

- As per Abhram’s law, the strength of workable concrete is only dependent on the water cement ratio.

- The volume of water in fresh concrete is directly related to the volume of empty pore spaces in hardened concrete. Similarly, the volume of cement is related to the solid volume in hardened concrete. Thus, the water cement ratio is a measure of the void volume relative to the solid volume in hardened cement paste and its strength goes up as the void volume goes down. Hence, lower the water-cement ratio, the lower is the void volume to solid volume ratio and stronger the hardened concrete. The same variation is also shown in the given figure.

- As it is evident from the curve shown, that at very low water-cement ratio the strength of concrete does not follow the curve shown by solid line but instead follows the dotted line curve. The reason for this behavior is that when the water cement ratio is low in a fresh-mix then, less water is available for the hydration of cement. Thus, some amount of cement is left unhydrated that leads to internal tension in concrete and causes weak bonds.

- For proper workability, the water cement ratio lies between 0.4 to 0.6. However, concrete compacted by vibrations displays higher strength even upto a water cement ratio of 0.3

- When w/c ratio is more than 0.6, the increased volume of hydrated products would not be able to occupy the space already filled with water. Hence, porosity increases and the strength decreases.

<< Previous | Next >>

Must Read: What is Construction Material?

WhatsApp Group

Join Now

Telegram Group

Join Now